What is 3D Laser Scanning?

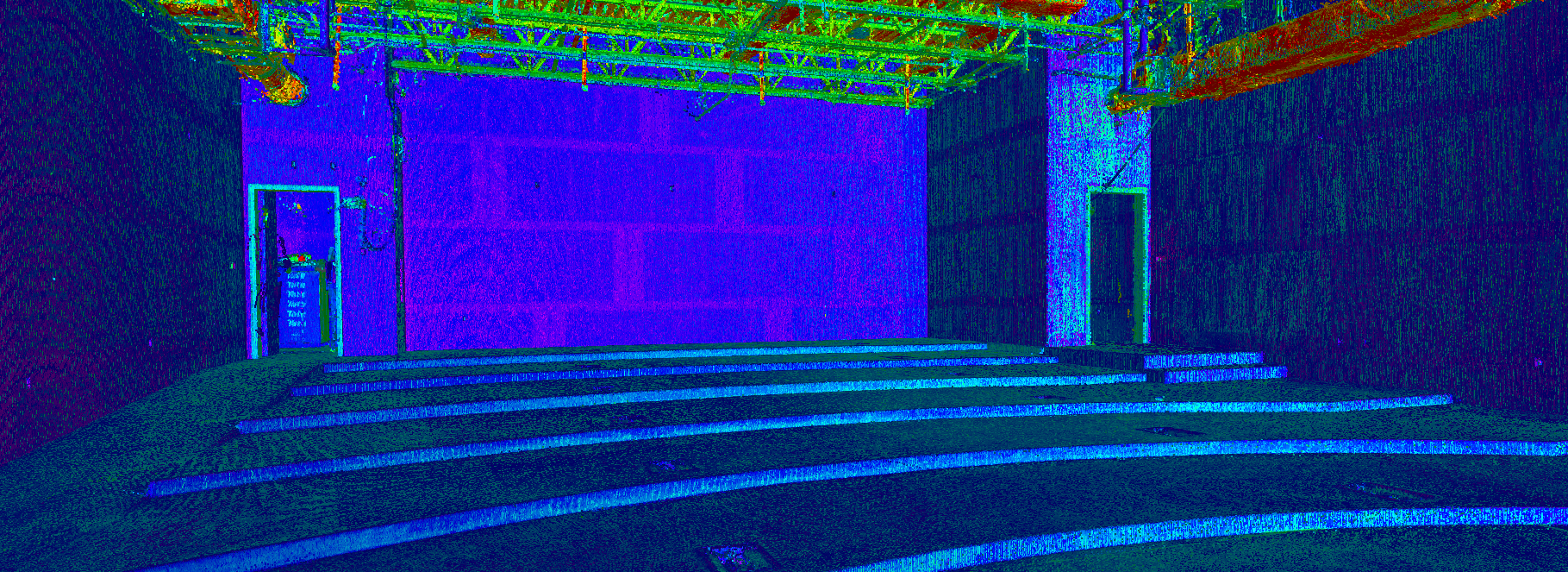

3D Laser Scanning, or LiDAR, technology can help you digitally capture the precise size and shape of your project, at any step along the way. LiDAR can scan an existing structure or object to collect millions of data points for astoundingly accurate measurements. Simply put, it calculates the distance of each point on the surface of the object in relation to the position of the scanner. With multiple overlapping scans, these data points are gathered into a “point cloud” that then digitally represents the scanned structure or object in three dimensions. We aren’t talking about the cloud on the internet where we store our cute puppy photos – rather, it is a cloud of points that represent a geometric shape on the surface of the object. After these point clouds are gathered from the scans, they can then be converted into a 3D CAD/BIM (Building Information Model) model for your use.

3D Laser Scanning, or LiDAR, technology can help you digitally capture the precise size and shape of your project, at any step along the way. LiDAR can scan an existing structure or object to collect millions of data points for astoundingly accurate measurements. Simply put, it calculates the distance of each point on the surface of the object in relation to the position of the scanner. With multiple overlapping scans, these data points are gathered into a “point cloud” that then digitally represents the scanned structure or object in three dimensions. We aren’t talking about the cloud on the internet where we store our cute puppy photos – rather, it is a cloud of points that represent a geometric shape on the surface of the object. After these point clouds are gathered from the scans, they can then be converted into a 3D CAD/BIM (Building Information Model) model for your use.

How can 3D laser scanning benefit your company and projects?

It makes your design work easier. The addition of the laser tape made things a bit easier, but we still have to double-check each measurement, record each one in relation to the rest of the structure on paper or pdf, and then finally enter those measurements into CAD. It is slow going with a high probability of errors. However, with 3D laser scanning, the scanner does all the data collection and digital input. One or two of Rogue Visual Design’s LiDAR specialists can document a project faster and more accurately than an entire team of individuals using conventional means. Look around your office, conference room, or industrial plant. Imagine how long it would take you to document the numerous measurements needed to produce an exact digital replica. If it’s more than a couple minutes, we can do better.

It makes your design work easier. The addition of the laser tape made things a bit easier, but we still have to double-check each measurement, record each one in relation to the rest of the structure on paper or pdf, and then finally enter those measurements into CAD. It is slow going with a high probability of errors. However, with 3D laser scanning, the scanner does all the data collection and digital input. One or two of Rogue Visual Design’s LiDAR specialists can document a project faster and more accurately than an entire team of individuals using conventional means. Look around your office, conference room, or industrial plant. Imagine how long it would take you to document the numerous measurements needed to produce an exact digital replica. If it’s more than a couple minutes, we can do better.

By its very nature, 3D laser scanning is highly flexible and usable in countless applications across virtually every industry. We focus on using it as an indispensable tool to assist you in documenting existing buildings for architectural, engineering, and construction projects. With this technology, we can digitally replicate anything, from the most minute details in a historic structure to the largest factory layout. All of this is done to save you time, money, and allow your staff focused on what they do best.