AMC UTC Theatre San Diego

Rogue Visual Design provided 3D laser scanning for AMC’s UTC 14-screen theater in San Diego. Our team captured key site details and developed a comprehensive BIM model. These enabled seamless planning with minimal disruption.

View ProjectAMC UTC Theatre San Diego

AMC's San Diego UTC Theatre

AMC Entertainment Holdings, Inc., is the largest movie exhibition company on the planet. Founded in 1920 and headquartered in Leawood, Kansas, AMC operates approximately 900 theaters and 10,000 screens globally. AMC is known for its innovative approach to the movie-going experience, including the deployment of its signature power-recliner seats, enhanced food and beverage choices, loyalty and subscription programs, and premium large format experiences. To remain at the forefront of their industry requires visionary customer insight, in-depth planning, and regular documentation of each of their properties.

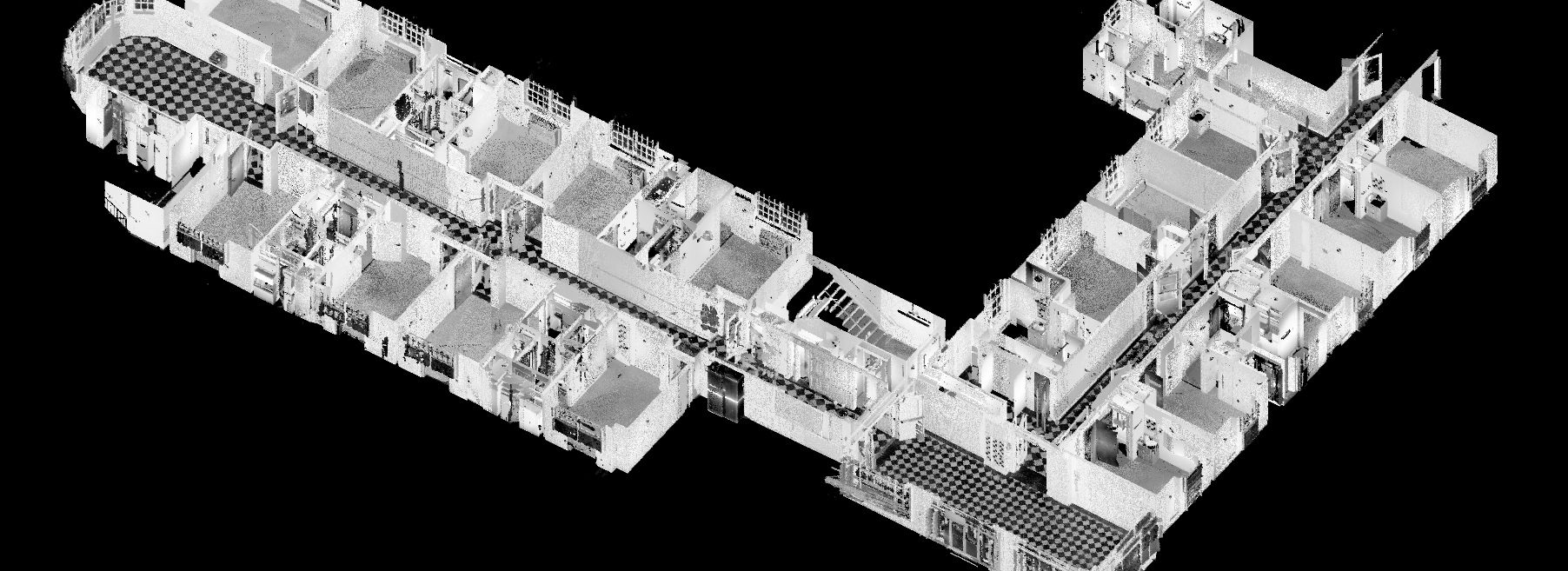

Nestled in the bustling heart of San Diego's UTC Shopping Mall, the AMC 14-screen theater embarked on a journey to breathe new life into this beloved venue. The recently acquired multiplex had some superficial updates and rebranding: however, it was ready to fully become part of the AMC family. For the design team to accomplish their work, they needed accurate architectural CAD/BIM models of the current site conditions. Rogue Visual Design’s expertise with laser scanning and Revit modeling made us the obvious choice to acquire the critical information.

A pair of our LiDAR specialists traveled to California to meticulously document the existing site conditions. The team coordinated the scanning schedule with theater staff to avoid any disruption to their patrons or normal business operation. Movie auditoriums were scanned between shows or after business hours. Projection booths and storage were captured during movie screenings. Common areas such as the lobby, concessions, corridors, and restrooms were mapped after the last show and movie goers had left for the night.

Each area had unique or critical features that needed to be documented. The size, location, and curvature of the silver screen, the location of the projection windows, and the floor height of the projection booth are all factors when selecting or configuring a projector. To lay out a seating configuration which would accommodate the new recliners, the design team needed the theater dimensions, screen location, riser heights, depth, and profile. The winding halls, the canted walls, theater's acoustic elements, the location of fire extinguishers, and emergency exits were all quickly gathered with LiDAR.

Collaboration between AMC and the architectural team was instrumental to the project’s success. Rogue Visual Design’s proficiency in laser scanning and Revit modeling facilitated efficient planning, design, and construction processes. The comprehensive BIM model allowed for better coordination and clash detection, reducing the likelihood of costly errors and rework during construction. The renovation project at the AMC UTC theater is a testament to AMC and their collaborative team’s commitment to excellence.

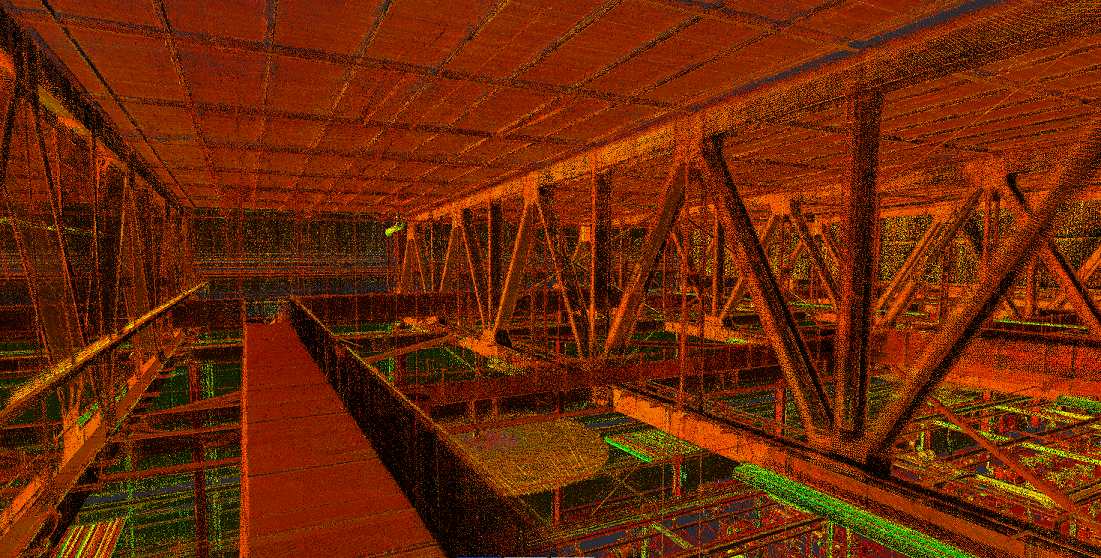

IC Bus – Tulsa

Tulsa is now the world’s largest school bus manufacturing hub. IC Bus, producing up to 74 buses daily. Rogue Visual Design used LiDAR scanning to optimize crane installation, ensuring precision and avoiding costly delays in their mile-long assembly line.

View ProjectIC Bus - Tulsa

Tulsa is now, based on volume, the School Bus Manufacturing Capitol of the WORLD. This comes after final deal negotiations in April of 2024 between the city of Tulsa and the Navistar Corporation to keep the manufacturing plant in Tulsa (ICBus | IC Bus - IC Bus in Oklahoma). That’s a big deal! School transportation is a critical business. They carry our most precious cargo. When parents give their trust to transport their children, it’s imperative that the bus, for safety and every other standard, is of the highest quality.

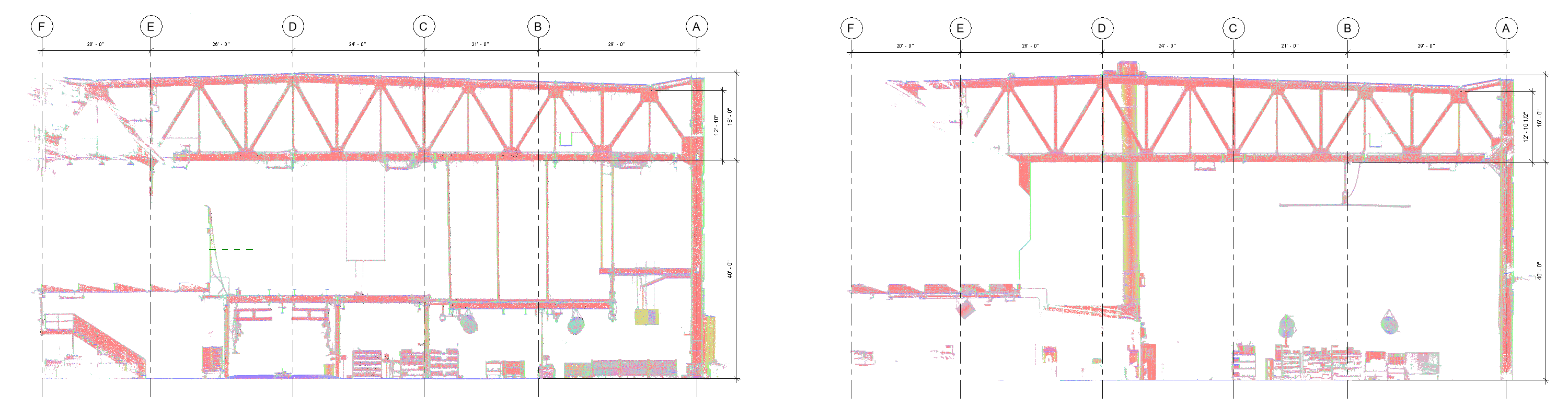

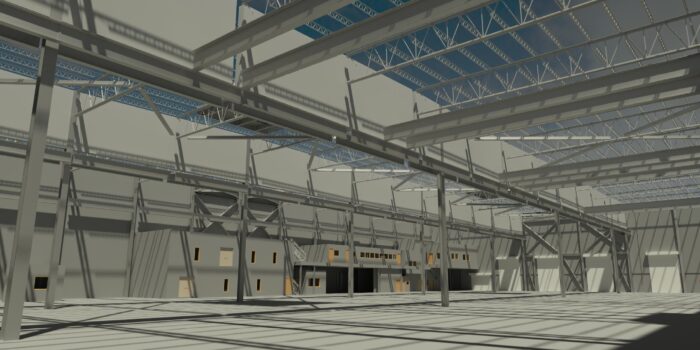

Already boasting an average of 68 buses a day with a maximum of 74 on a perfect day, IC Bus planned to expand their manufacturing capabilities to meet the needs of their customers. They also wanted to maximize use of their current assets before building more space. The current journey of a bus through the factory assembly line, from start to finish, is nearly a mile! Integral to that journey are hoist cranes used throughout the factory to move bus shells, seats, engines, transmissions, and a multitude of other assemblies. The challenge for the design team was to coordinate the numerous attachment locations needed for the new cranes and hoists within the congested space. The best option was to bring in a LiDAR team to measure critical areas, notably the roof trusses from which the new cranes will be attached/suspended.

Rogue was able to enter this space and quickly scan three areas totaling approximately 35,000 ft2. LiDAR eliminated the tedious act of scouring the giant factory on lifts and struggling to determine what trusses would be best used or where new steel could be attached. The trusses within the plant are assembled from structural steel riveted together with plates. They are about 15 feet deep with the bottom being 40 feet above the floor. From the ground, the trusses look the same; however, laser scanning reviled each was unique. There were several inches of variation in gusset plate size and location. The new structure could not attach to these gusset plates. The new steel also needed to avoid lights, cable tray, and numerous auxiliary structures that have been added over the years. Had brackets and support steel been perfricated from ground measurements and old drawings, the assemblies would not have fit, and the project would have been delayed. Imagine the wasted time, material, and equipment expense in that scenario.

With the LiDAR point clouds, our CAD/BIM team generated the desired documentation allowing the project design team to quickly evaluate and determine where to position the equipment and support structures.

Historic Northeast Lofts

Located in the heart of Kansas City, MO, the Historic National Cloak and Suit Company property is ready for a new chapter.

View ProjectHistoric Northeast Lofts

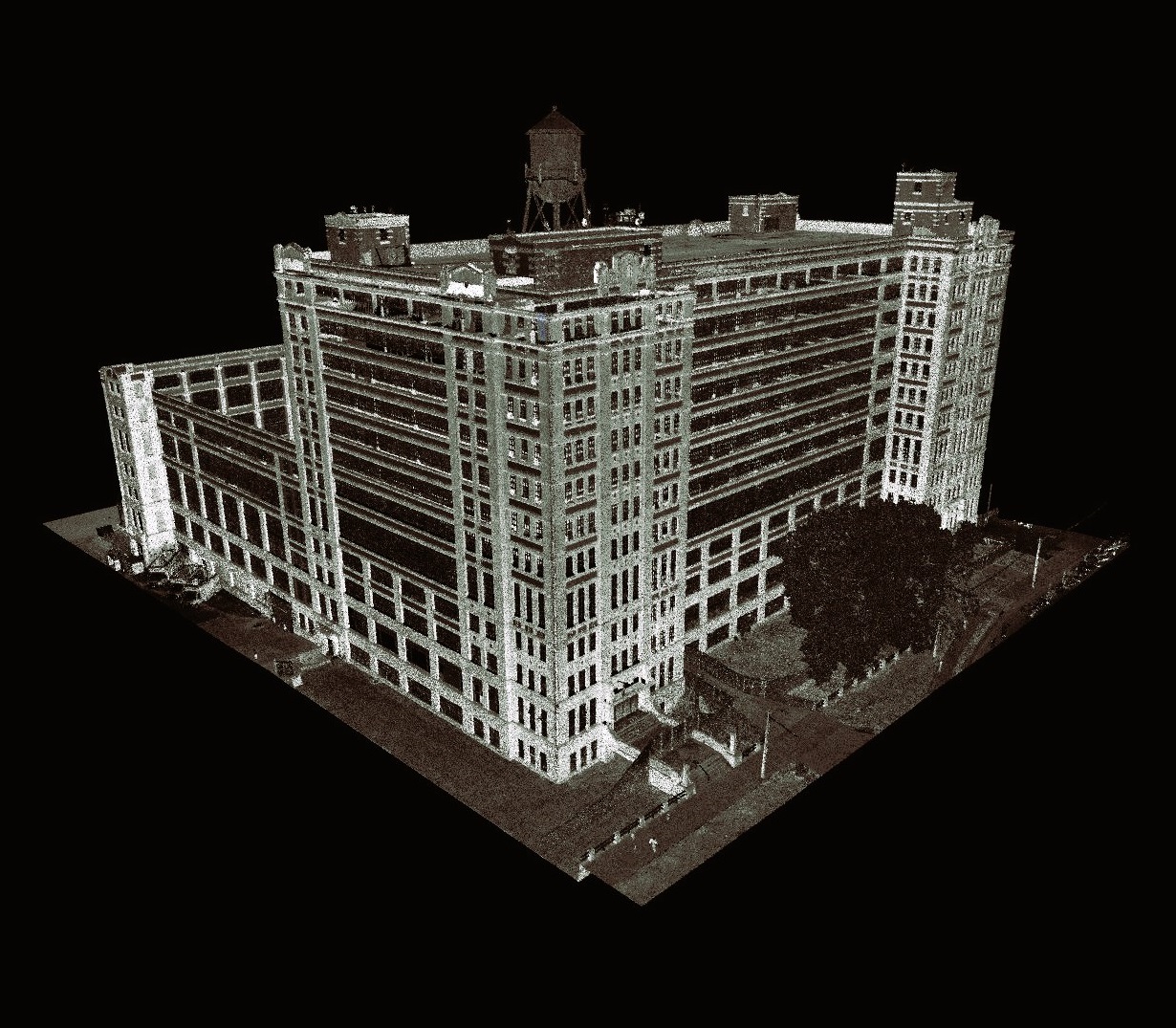

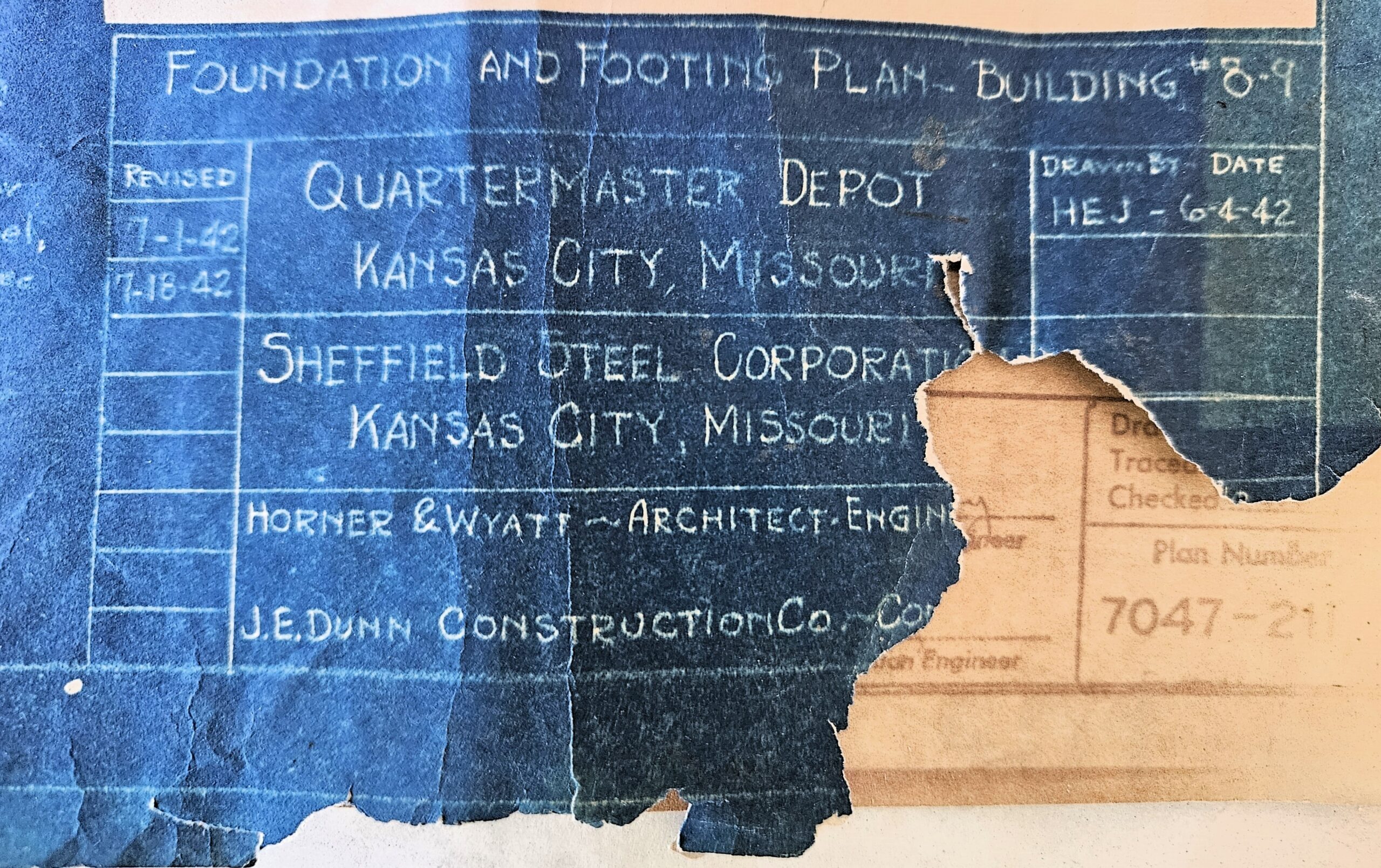

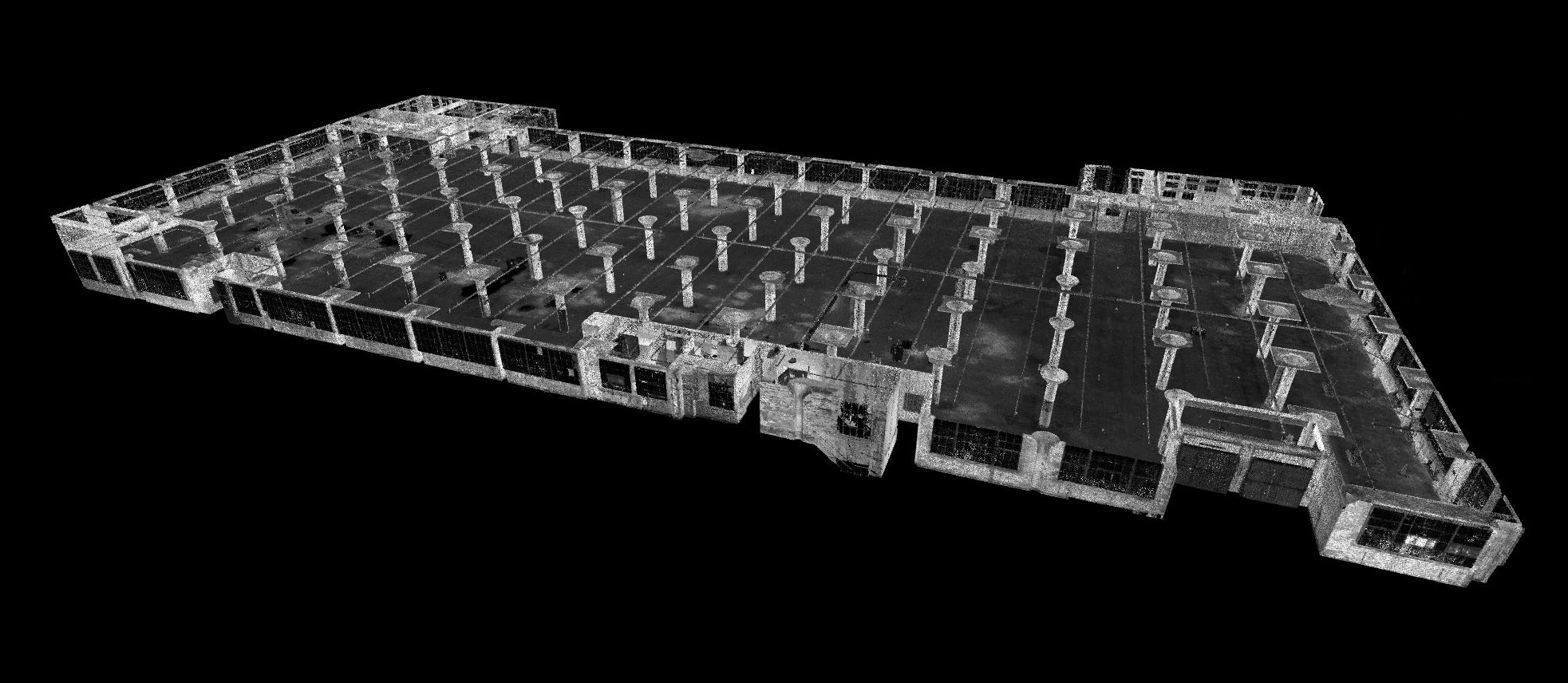

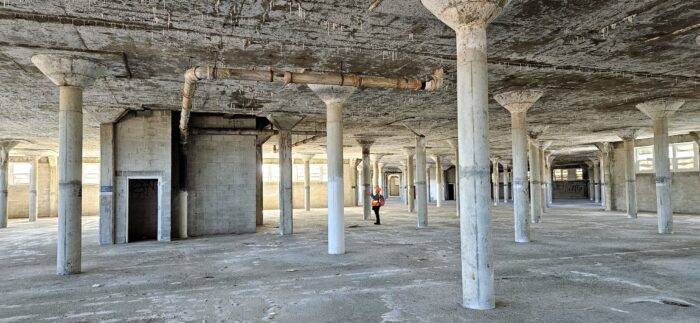

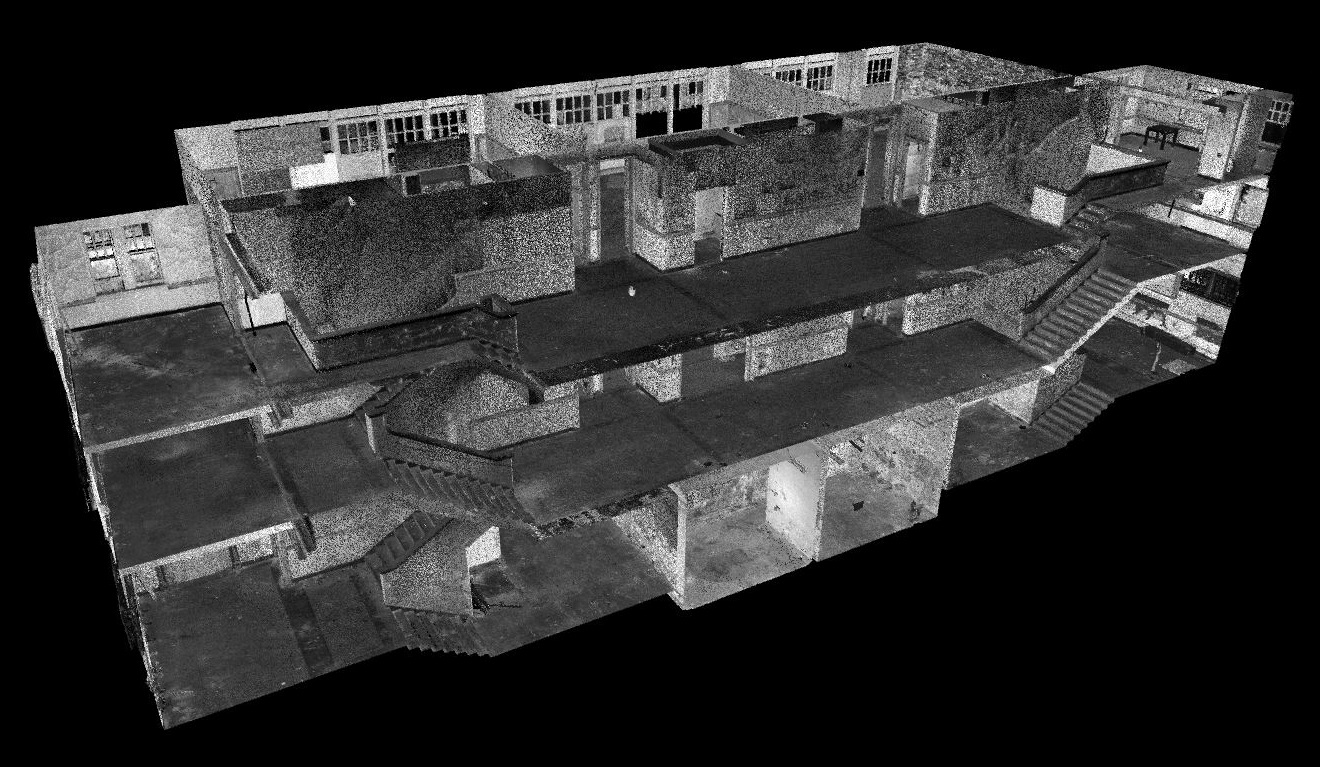

Located in the heart of Kansas City, MO, the Historic National Cloak and Suit Company property is ready for a new chapter. Built over 100 years ago, the main building once contained a hospital, cafeteria, rec room, courts and ground for sports, and more for the over 2,000 employees that worked there. Starting in World War II and continuing through 1953, the property served as a quartermaster’s depot and included a unit for processing the personal items of our nation’s fallen. In 1948, the adjutant general’s department of the Army established the Kansas City Records Center there. Following a feasibility study in 1977, the General Services Administration deemed the building unusable and abandoned the site. For the past few decades, it has served as a self-storage center.

Now shadows of their former selves, the 7 buildings across the 22-acre property presented numerous challenges for Rogue Visual Design’s reality capture teams. Each day began with a thorough safety check of the areas to be documented. Standing water, ice, large open shafts, interior vegetation, thousands of dead birds, subzero temperatures, and cavernous spaces engulfed in darkness all presented unique risks which needed to be planned for. Numerous UAS/drone flights, and several scanning teams crisscrossed the site methodically documenting each building inside and out.

The LiDAR data, Revit models, and orthomosaics images Rogue delivered to the design team provided precise existing site conditions. Our RTC360 laser scanner pierced the darkness and dilapidation. Photos from our aerial drone were processed into an orthomosaic site map and orthomosaic elevations of the 12-story main building’s exterior walls. Rogue’s work saved the project stakeholders an incalculable amount of time and money. They were not required to make numerous site visits, spend hundreds of hours measuring, or construct scaffolding to conduct a preliminary inspection of the building’s exterior. Rogue’s expertise and experience offered the necessary lifeline.

The LiDAR data, Revit models, and orthomosaics images Rogue delivered to the design team provided precise existing site conditions. Our RTC360 laser scanner pierced the darkness and dilapidation. Photos from our aerial drone were processed into an orthomosaic site map and orthomosaic elevations of the 12-story main building’s exterior walls. Rogue’s work saved the project stakeholders an incalculable amount of time and money. They were not required to make numerous site visits, spend hundreds of hours measuring, or construct scaffolding to conduct a preliminary inspection of the building’s exterior. Rogue’s expertise and experience offered the necessary lifeline.

ARROWHEAD FIELD LIGHTING

As Kansas City prepares to host the 2026 World Cup, FIFAs rigorous standards require numerous upgrades to Arrowhead Stadium. Modernizing the field lighting was among the mandatory updates. Rogue Visual Design was a vital partner in this endeavor deploying 3D LiDAR scanning technology to maintain safety, overcome challenges, deliver the most accurate and comprehensive data…

View ProjectARROWHEAD FIELD LIGHTING

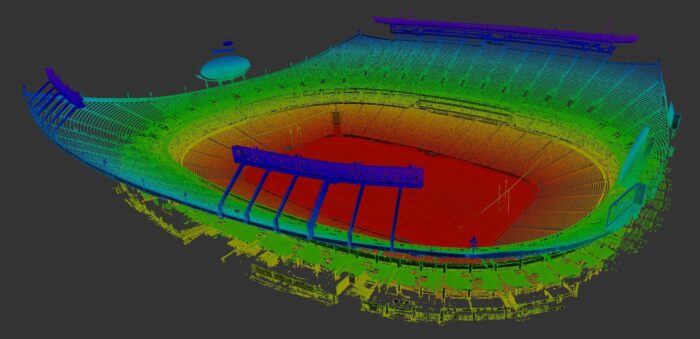

As Kansas City prepares to host the 2026 World Cup, FIFAs rigorous standards require numerous upgrades to Arrowhead Stadium. Modernizing the field lighting was among the mandatory updates. Rogue Visual Design was a vital partner in this endeavor deploying 3D LiDAR scanning technology to maintain safety, overcome challenges, deliver the most accurate and comprehensive data possible.

Due to elevation and the complex fixtures, the lighting structures at Arrowhead are best documented through the use of LiDAR technology. 3D Laser Scanning (LiDAR) offers distinct advantages over traditional methods such as a total station. Rogue’s RTC360 laser scanner captures 2 million measurements a second. A standard total station can only gather a few hundred in a day. A scan generated point cloud is a 3D representation complete with all the imperfections and context of the environment. A total station gathers only a handful of key points. With incomplete data and lacking context of the environment, more interpretation is required, there is a greater chance of error, and an increased need for follow-up trips to gather additional/missed survey points. Comprehensive LiDAR data gives stakeholders and designers precision, depth and detail, simplifying their task of creating accurate models for retrofitting while enhancing planning efficiency. LiDAR's ability to swiftly and accurately map environments makes it suited for large-scale, detail-oriented projects like this one at Arrowhead Stadium.

Rogue Visual Design is not directly involved in the manufacturing process; however, the accuracy of our measurements assures the fabricated components will fit perfectly within the existing stadium infrastructure. The LiDAR point clouds are brought into the CAD environment. Each assembly is carefully crafted to fit into the existing steel frame, each mount designed to bolt seamlessly into position, and every new light is digitally aimed and luminous virtually modeled and verified before a single piece of metal is cut.

This project highlights Rogue Visual Design’s commitment to implementing cutting-edge technology to deliver solutions that are innovative, practical, and valuable to the project stakeholders. These improvements will not only fulfill FIFA’s specifications, but also enhance the spectator experience for all future events at the venue. They ensure that Arrowhead Stadium remains a premier venue for both local and international events. Arrowhead is setting new standards, literally, in stadium lighting and will be ready to shine on the world stage in 2026. We are proud of our contribution.

BNSF – Alliance, NE

An operational train repair facility of over 300,000 sq. ft. needed a Revit model to assist with designing a new fire suppression system.

View ProjectBNSF - Alliance, NE

Over the past 170 years, nearly 400 railroads merged or were acquired to form the BNSF Railway. When it is time for maintenance, many diesel locomotives and coal cars operating on BNSF railroads today will pass through a repair facility in Alliance, Nebraska. A visit to the facility reveals that the Alliance shop performs brake replacement, oil changes, wheel replacement, and heavy diesel maintenance.

The task at hand for Rogue Visual Design might seem daunting for the inexperienced. We were charged with laser scanning more than 300,000 square feet of parts storage, numerous office spaces, repair shops, and maintenance bays with massive locomotives and rail cars moving through. Not content to stop there, the team flew a drone over roughly 60 acres of property surrounding the facility, collecting vast amounts of data. The flight combined with LiDAR scans of the structure provided the modelling team the information needed to create a detailed Revit model of the building's architectural, structural, and fire sprinkler systems. Given the immense size of the building and the numerous spaces within it, this may seem like a monumental task, but it is a typical day's work for Rogue's skilled BIM team.

Through our partnership, BNSF will benefit from the installation of a new fire suppression system. The integration of spatial data collected by our reality capture specialists into the Revit model, offers a robust foundation for analysis. Engineers can identify potential obstructions, locate optimal system placement, and determine the most effective routing of pipes. The data also ensures systems are designed to meet safety regulations and address specific project requirements. This process identifies conflicts between fire suppression components and other building systems, such as electrical, HVAC, or structural elements. By resolving clashes during the design phase, costly and time-consuming modifications during construction can be avoided, leading to a more efficient and streamlined process.

The amalgamation of Revit models, LiDAR scans, and Drone technology provides a wealth of information that can be harnessed for performance optimization. This data-driven approach empowers engineers to fine-tune their projects. The blend of tools presents an unparalleled opportunity for the construction and engineering industry. By leveraging these powerful technologies, professionals can save valuable time and money throughout the project lifecycle. The benefits are significant, from accurate site documentation to streamlined design processes and improved construction site management. By embracing this innovative technology, construction and engineering professionals can deliver projects with unparalleled efficiency, unrivaled accuracy, and reduced costs. Moreover, the data collected can be leveraged for future projects further maximizing its value and utility.

Pitt @ 1902 Broadway – Pittsburgh, KS

A 45,000 sq. ft. occupied apartment building with no floor plan needing a Revit model for renovation.

View ProjectPitt @ 1902 Broadway - Pittsburgh, KS

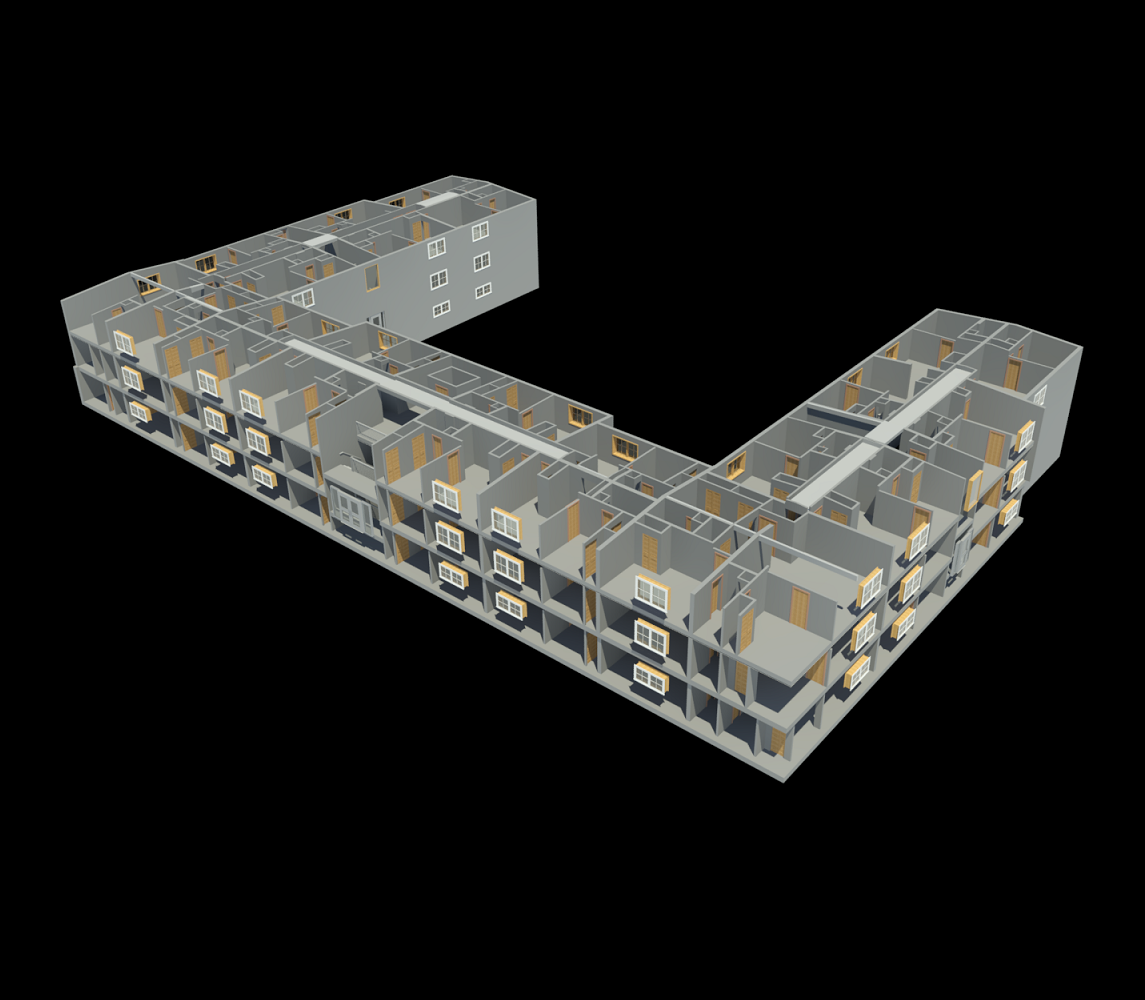

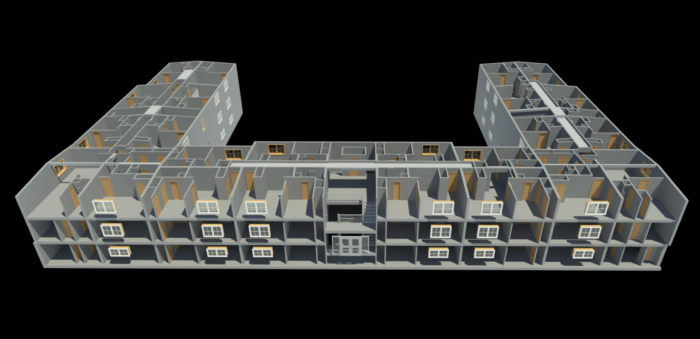

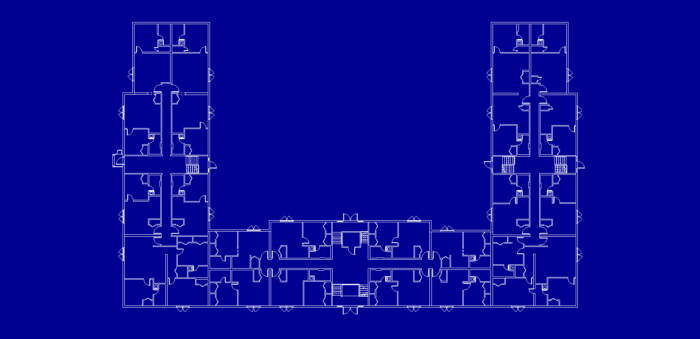

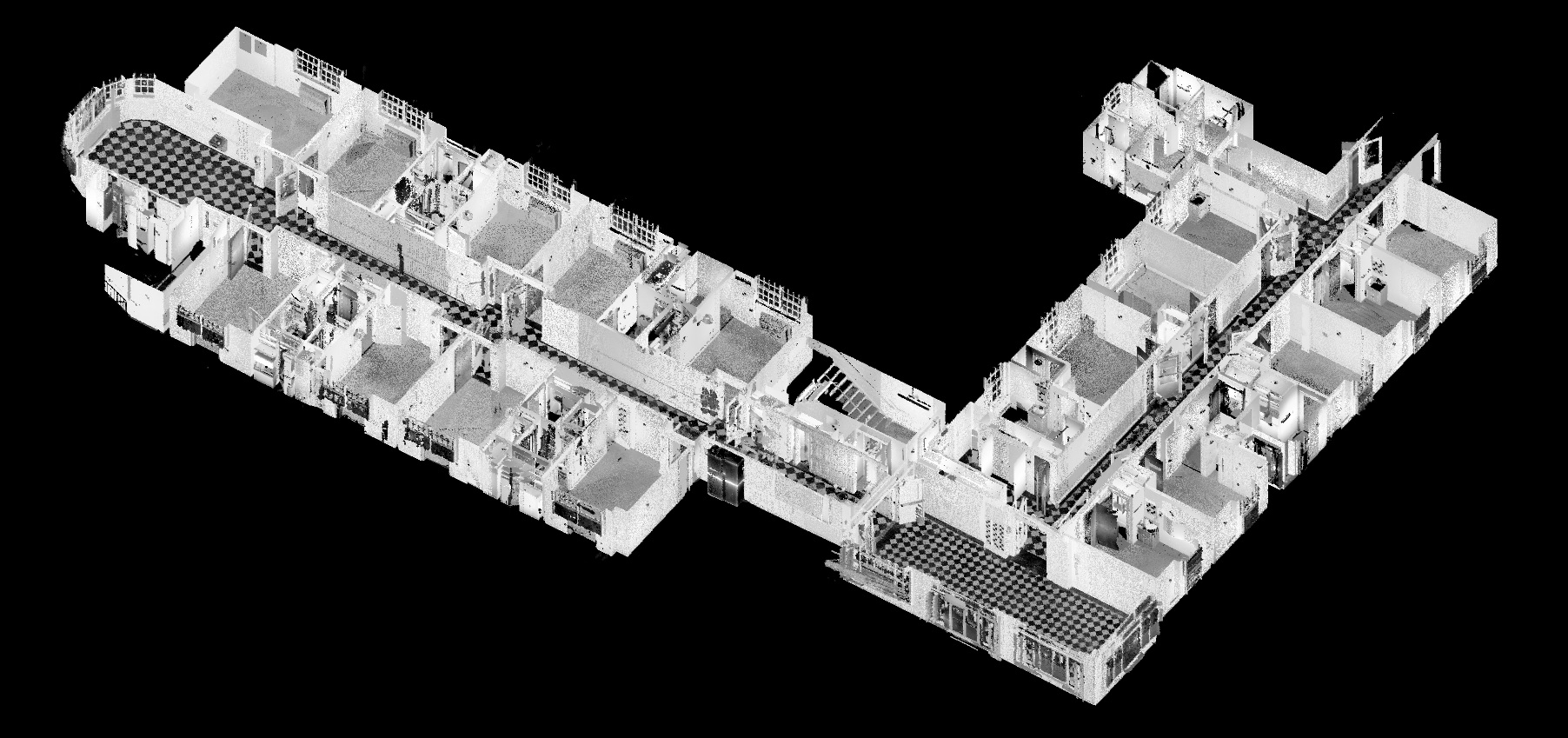

Pitt @ 1902 Broadway Building D is one of several apartment buildings across the street from the campus of Pittsburg State University in Pittsburg, Kansas. The 45,000-square-foot, three-story brick edifice, built around a central courtyard, was set to undergo significant remodeling by the property owner. The architectural firm engaged for this renovation needed accurate floor plans as none existed for the building. To remedy this, the architect reached out to Rogue Visual Design to document the interior and exterior of the apartment building.

Apartment buildings, by their very nature, pose a detailed task due to the multitude of scans required for thorough interior documentation. Building D, composed of 57 distinct apartment units, each housing a variety of smaller spaces such as bedrooms, bathrooms, and closets, was no exception. Additionally, the hallways, stairwells, laundry, and a variety of other rooms also required scanning. Despite the building being 75-80% occupied by residents, our experienced team efficiently completed over 1,000 separate laser scans to accurately represent these myriad spaces.

With the LiDAR scans collected and registered, our BIM team developed and delivered the LOD 300 Revit model to the architect within a matter of days. This 3D model provided the owner and the architect with the most up-to-date as-built conditions of the building.

Rogue Visual Design holds immense pride in the unmatched accuracy and meticulous detail captured by our state-of-the-art 3D Laser Scanners and our highly skilled team. The completion of over 1,000 scans within an apartment complex is an affirmation of our proficiency, a testament to our adaptability. Our wide-ranging experience, documenting millions of square feet, instills in us the confidence that we can scan and deliver high-quality models for any project, irrespective of the building's size.

At Rogue Visual Design, we consistently bring a robust blend of experience, efficiency, and reliability to each task. We stand ready to apply this same meticulous attention to detail and problem-solving approach to future projects, delivering results that consistently exceed expectations. We look forward to bringing this same approach to your next project.

Central Plains Cement Company – Alternative Fuel Pipe Reconfiguration

Using LiDAR scan measurements to assist with reconfiguring fuel pipes to a 2,640℉ kiln without shutdowns.

View ProjectCentral Plains Cement Company – Alternative Fuel Pipe Reconfiguration

For well over a century, Central Plains Cement Company has been supplying Portland cement of varying grades for industrial, civil, and personal concrete projects throughout the Midwest. Staying at the forefront of the cement industry, Central Plains has been pioneering the use of alternative fuel sources (ground solid waste) to fire their cement kilns. This innovative approach has not only reduced dependence on traditional fossil fuels but has also led to significant reductions in production costs.

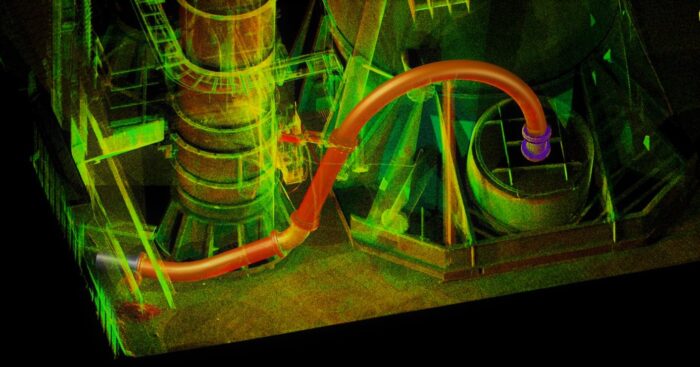

The kiln, being the primary source of CO2 emissions in the cement production process, is a crucial area of focus for both Central Plains and the wider industry. Central Plains sought to reconfigure the alternative fuel pipe to a new inlet spout, aiming for a more efficient burn and greater heat recovery. In response to this need, the experts at Rogue Visual Design were called upon to employ our precision 3D laser scanning (LiDAR) to aid in the design of this new configuration. The challenge at hand involved obtaining precise location, alignment, and bolt orientation of both the existing flange connection and the new spout.

Documenting the pipe and spout configuration around a kiln, which can reach temperatures exceeding 1450 degrees Celsius (2640 degrees Fahrenheit), is a complex and potentially hazardous task. However, our highly skilled LiDAR scanning team was able to meticulously capture the entire pipe, spout configuration, and the intricate surrounding area without compromising on safety. The ability of our scanners to collect this data from a safe distance meant that the kiln did not need to be shut down, ensuring uninterrupted operations for Central Plains.

The detailed data acquired allowed Central Plains to minimize the kiln's downtime by prefabricating possible pipe configurations. This empowered them to try out different designs configurations until they identified one that perfectly suited their needs. With the pipe geometry meeting their expectations, Central Plains requested our team's expertise once again to scan the temporary pipe. The abrasive nature of the material being transported necessitated a robust material choice for the permanent alternative fuel line. Using the new LiDAR data, our team delivered a second registered point cloud and a 3D AutoCAD model of the approved pipe. The plant was then able to fabricate a new pipe using more durable material based on our detailed model.

Central Plains Cement Company recognizes the value our experienced LiDAR scanning teams and advanced equipment bring to projects with challenging conditions, such as this one. We have demonstrated the ability to accurately, efficiently, and safely document existing conditions for complex projects, often within a matter of hours. We do this while maintaining a safe working distance, minimizing or even eliminating operational downtime. If you have a complex project that requires precise measurements without equipment downtime, consider going Rogue. We deliver results fast, safely, and with unparalleled precision. Let Rogue Visual Design be your partner for your next challenging project.

A&M Manufacturing

LiDAR scanning enables safe and efficient MEP upgrades for A&M manufacturing.

View ProjectA&M Manufacturing

Many of our clients specialize in Mechanical Electrical Plumbing (MEP) projects. One such client was selected by A&M Manufacturing, in Spring Hill, Kansas, to design upgrades to plants electrical equipment. This would require connecting the newly installed equipment with the transformer and other electrical equipment outside of the building. The proposed upgrade included adding a Master Control Center (MCC) room within the manufacturing facility which would increase their production capacity. A&M Manufacturing, a subsidiary of The Clorox Co., is a major supplier of Fresh Step and Scoop Away Kitty Litter for the central United States.

As with many of our projects, the existing documentation for the building either did not exist, or lacked enough detailed information to plan the electrical upgrades. To remedy this lack of crucial information on the building layout, the electrical engineer contacted Rogue Visual Design to collect 3D laser scans (LiDAR) of the building and the surrounding environment. More specifically, the Rogue scanning team was tasked with documenting two optional paths for the electrical connections between the equipment inside and outside of the building.

When we assessed the site conditions prior to scanning, we discovered ice and snow-covered portions of the roof. These extremely slippery conditions presented a safety challenge to our original plans for documenting the rooftop route. However, our flexible and experienced scanning team devised a way to scan the roof from safe vantage points without setting foot on it. We then meticulously pieced together the roof scans with those taken at ground level and the building interior. A 3D Revit model of the area was then developed from LiDAR data set and delivered to the MEP engineering team. They were able to effectively evaluate both optional routes and design the most efficient build for the electrical connections.

Assignments such as this are typical of MEP projects. Our clients need to know the true existing “as-built” conditions to design the most efficient way to complete the needed upgrade. Let the Rogue Visual Design Team help you with your next MEP project. We will deliver an industry leading Revit model that will meet or exceed your design expectations.

As with many of our projects, the existing documentation for the building either did not exist, or lacked enough detailed information to plan the electrical upgrades. To remedy this lack of crucial information on the building layout, the electrical engineer contacted Rogue Visual Design to collect 3D laser scans (LiDAR) of the building and the surrounding environment. More specifically, the Rogue scanning team was tasked with documenting two optional paths for the electrical connections between the equipment inside and outside of the building.

When we assessed the site conditions prior to scanning, we discovered ice and snow-covered portions of the roof. These extremely slippery conditions presented a safety challenge to our original plans for documenting the rooftop route. However, our flexible and experienced scanning team devised a way to scan the roof from safe vantage points without setting foot on it. We then meticulously pieced together the roof scans with those taken at ground level and the building interior. A 3D Revit model of the area was then developed from LiDAR data set and delivered to the MEP engineering team. They were able to effectively evaluate both optional routes and design the most efficient build for the electrical connections.

Assignments such as this are typical of MEP projects. Our clients need to know the true existing “as-built” conditions to design the most efficient way to complete the needed upgrade. Let the Rogue Visual Design Team help you with your next MEP project. We will deliver an industry leading Revit model that will meet or exceed your design expectations.

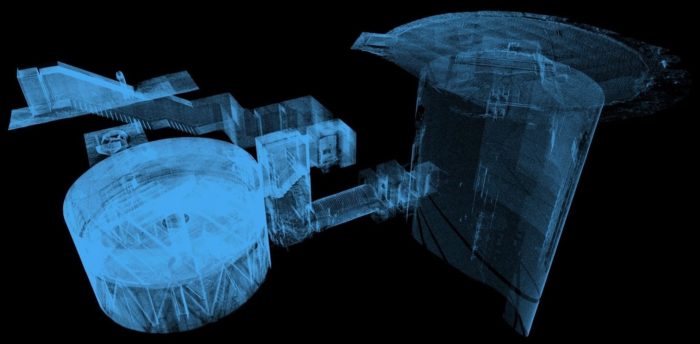

Central Plains Cement Company – Barge Loadout

Utilizing our UAV / drones and scanners to create a CAD model of a barge loadout facility along a steep riverbank, inaccessible from the water side.

View ProjectCentral Plains Cement Company - Barge Loadout

For well over a century, Central Plains Cement Company has provided Portland cement of varying grades for industrial, civil, and personal projects throughout the Midwest. To deliver the cement, Central Plains makes use of its location on the Missouri River to load barges destined for midwestern markets. Their Kansas City barge loadout facility had been in operation for decades and needed to be replaced.

To prepare for the engineering and construction required to install the new barge loadout, Central Plains called on the trusted reality capture professionals at Rogue Visual Design. Central Plains asked us to document the aging loadout structure, all its associated equipment, and the adjacent topography along the riverbank. As always, our expert team was up to the task. The challenge for this project was that a large portion of the structure, sheet piles, and fender piles were only visible from the water side of the loadout. With a deep and fast-moving channel and steep riverbanks, the Missouri River did not provide stable footing for our LiDAR Scanners; however, it is perfect for our UAS/drone. As such, we brought in our UAS/drone to document the components that would simply not have been possible with a stationary laser scanner.

Our team then went to work. We deployed our 3D LiDAR scanner to document the facility from the land side of the loadout and our UAS/drone to document the water side. The major elements of the barge loadout included 2 side-by-side piers that jutted out over the river and were supported by steel columns driven into the river channel and dry bank. Vertically placed steel sheet piles and fender piles surrounded the piers and protected them from the barges while they were being loaded. Two mooring winches helped guide and secure the barges into place for loading. We relied on our years of experience and advanced equipment to carefully document this entire facility including several acres of the surrounding topography (both on and off shore).

Back at the office, our talented BIM team processed the drone and scan data and created a Revit model of the existing loadout and surrounding area. The model documented the as-built conditions of the structure, and the mechanical systems used to load the cement onto the barges below. We also provided a 3D contour drawing of the area surrounding the loadout structure. The information we delivered proved to be immediately useful in not only designing the needed upgrades but also in helping to troubleshoot during the construction.

To prepare for the engineering and construction required to install the new barge loadout, Central Plains called on the trusted reality capture professionals at Rogue Visual Design. Central Plains asked us to document the aging loadout structure, all its associated equipment, and the adjacent topography along the riverbank. As always, our expert team was up to the task. The challenge for this project was that a large portion of the structure, sheet piles, and fender piles were only visible from the water side of the loadout. With a deep and fast-moving channel and steep riverbanks, the Missouri River did not provide stable footing for our LiDAR Scanners; however, it is perfect for our UAS/drone. As such, we brought in our UAS/drone to document the components that would simply not have been possible with a stationary laser scanner.

Our team then went to work. We deployed our 3D LiDAR scanner to document the facility from the land side of the loadout and our UAS/drone to document the water side. The major elements of the barge loadout included 2 side-by-side piers that jutted out over the river and were supported by steel columns driven into the river channel and dry bank. Vertically placed steel sheet piles and fender piles surrounded the piers and protected them from the barges while they were being loaded. Two mooring winches helped guide and secure the barges into place for loading. We relied on our years of experience and advanced equipment to carefully document this entire facility including several acres of the surrounding topography (both on and off shore).

Back at the office, our talented BIM team processed the drone and scan data and created a Revit model of the existing loadout and surrounding area. The model documented the as-built conditions of the structure, and the mechanical systems used to load the cement onto the barges below. We also provided a 3D contour drawing of the area surrounding the loadout structure. The information we delivered proved to be immediately useful in not only designing the needed upgrades but also in helping to troubleshoot during the construction.

While installing new piles, an old tieback failed causing the sheet piles to shift. To assess the extent of movement, the engineers brought the Rogue Visual Design Team back to document the construction area and compare it with our original scans. With the additional information, the engineers were able to assess the situation, correct for the tieback failure, and proceed with construction.

Once the new barge loadout was complete, Central Plains called us back out to document the newly installed facility. Central Plains wanted to ensure they had a baseline model for the newly built structure so they would be more prepared to make for any future improvements in the future. Documenting a large cement loading facility suspended over an unpredictable river certainly presents its own challenges. However, our years of experience, expert reality capture and BIM specialists, and extensive tool chest allows us to successfully tackle complex projects.

However, nothing is too difficult for our expert reality capture team and BIM specialists.

We are honored our work is so highly valued by our partners at Central Plains Cement Company. We look forward to working with you on your next long-term documentation project regardless of the challenges it may present.

While installing new piles, an old tieback failed causing the sheet piles to shift. To assess the extent of movement, the engineers brought the Rogue Visual Design Team back to document the construction area and compare it with our original scans. With the additional information, the engineers were able to assess the situation, correct for the tieback failure, and proceed with construction.

Once the new barge loadout was complete, Central Plains called us back out to document the newly installed facility. Central Plains wanted to ensure they had a baseline model for the newly built structure so they would be more prepared to make for any future improvements in the future. Documenting a large cement loading facility suspended over an unpredictable river certainly presents its own challenges. However, our years of experience, expert reality capture and BIM specialists, and extensive tool chest allows us to successfully tackle complex projects.

However, nothing is too difficult for our expert reality capture team and BIM specialists.

We are honored our work is so highly valued by our partners at Central Plains Cement Company. We look forward to working with you on your next long-term documentation project regardless of the challenges it may present.

Central Plains Cement Company – Raw Mill Duct

Using UAV / Drone photogrammetry and LiDAR / Laser Scans to verify critical connection ensuring a seamless installation of new160ft duct.

View ProjectCentral Plains Cement Company - Raw Mill Duct

Since 1905, Central Plains Cement Company has provided Portland cement of varying grades for industrial, civil, and personal concrete projects throughout the Midwest. To create the cement that has provided the foundation for much of our midwestern infrastructure, Central Plains extracts a local source of raw limestone and mixes it with additional elements. One step in this limestone extraction process involves blowing the chunks of crushed limestone through a massive duct that is roughly 160’ long and 7’-9” in diameter. This duct is mounted between three towers and runs at a 63-degree angle.

Although the duct is made of resilient material, the over 20-year-old duct had reached the end of its design life and it needed to be replaced. For the new duct, Central Plains wanted to install one with a larger diameter. However, the expanded diameter of the proposed duct would require changes to its supports, transitions, and connection to the mill at its base on the lower tower. The new one would be fabricated off site and the crew had a limited window to complete the installation during the plant’s scheduled maintenance shutdown. Before the plant went through the arduous task of removing the old duct and lifting this immense new one into place, the engineering team needed to confirm it would fit. Without this duct, the plant does not operate.

The configuration of the existing duct was based on CAD drawings created in 1999. Central Plains wanted to be sure that the original drawings matched the current “as built” conditions of the duct as it existed over 20 years after its initial fabrication and installation. Knowing the current condition and configuration of the duct would allow them to ensure that the new one, which was already being fabricated, would fit on the new supports and connections. Having the new duct fit precisely would eliminate any additional down time for the plant.

Knowing the value of our work from several previous projects, Central Plains hired the Rogue Visual Design team to document the existing duct. Using a combination of our stationary laser scanner and UAS/drone, we were able to capture the exterior of the entire duct and its connections while the duct was still in operation. Our Leica scanner is an incredible machine with good range and impressive accuracy; however, this project pushed its limits. Considerable shaking caused by two 50 ton rolling mills at the base of the duct, and nearly 110’ vertical distance between two of the platforms presented significant challenges. As always, the Rogue team was up to the task. Using our years of experience and diverse tool set, we were able to complete the scans and flight within a few hours.

Once the drone and scan data sets were processed back at the office, our talented BIM team created an updated Revit model of the existing duct. This new model incorporated the original design from the .pdf with the existing as-built conditions. The 3D model we created provided Central Plains the specific dimension information needed to determine if the new duct would fit properly prior to installation. The engineering team was able to ensure the new duct was fabricated to fit. The installation at the plant went smoothly and was completed during the short maintenance shutdown.

The configuration of the existing duct was based on CAD drawings created in 1999. Central Plains wanted to be sure that the original drawings matched the current “as built” conditions of the duct as it existed over 20 years after its initial fabrication and installation. Knowing the current condition and configuration of the duct would allow them to ensure that the new one, which was already being fabricated, would fit on the new supports and connections. Having the new duct fit precisely would eliminate any additional down time for the plant.

Knowing the value of our work from several previous projects, Central Plains hired the Rogue Visual Design team to document the existing duct. Using a combination of our stationary laser scanner and UAS/drone, we were able to capture the exterior of the entire duct and its connections while the duct was still in operation. Our Leica scanner is an incredible machine with good range and impressive accuracy; however, this project pushed its limits. Considerable shaking caused by two 50 ton rolling mills at the base of the duct, and nearly 110’ vertical distance between two of the platforms presented significant challenges. As always, the Rogue team was up to the task. Using our years of experience and diverse tool set, we were able to complete the scans and flight within a few hours.

Once the drone and scan data sets were processed back at the office, our talented BIM team created an updated Revit model of the existing duct. This new model incorporated the original design from the .pdf with the existing as-built conditions. The 3D model we created provided Central Plains the specific dimension information needed to determine if the new duct would fit properly prior to installation. The engineering team was able to ensure the new duct was fabricated to fit. The installation at the plant went smoothly and was completed during the short maintenance shutdown.

North Kansas City Hospital

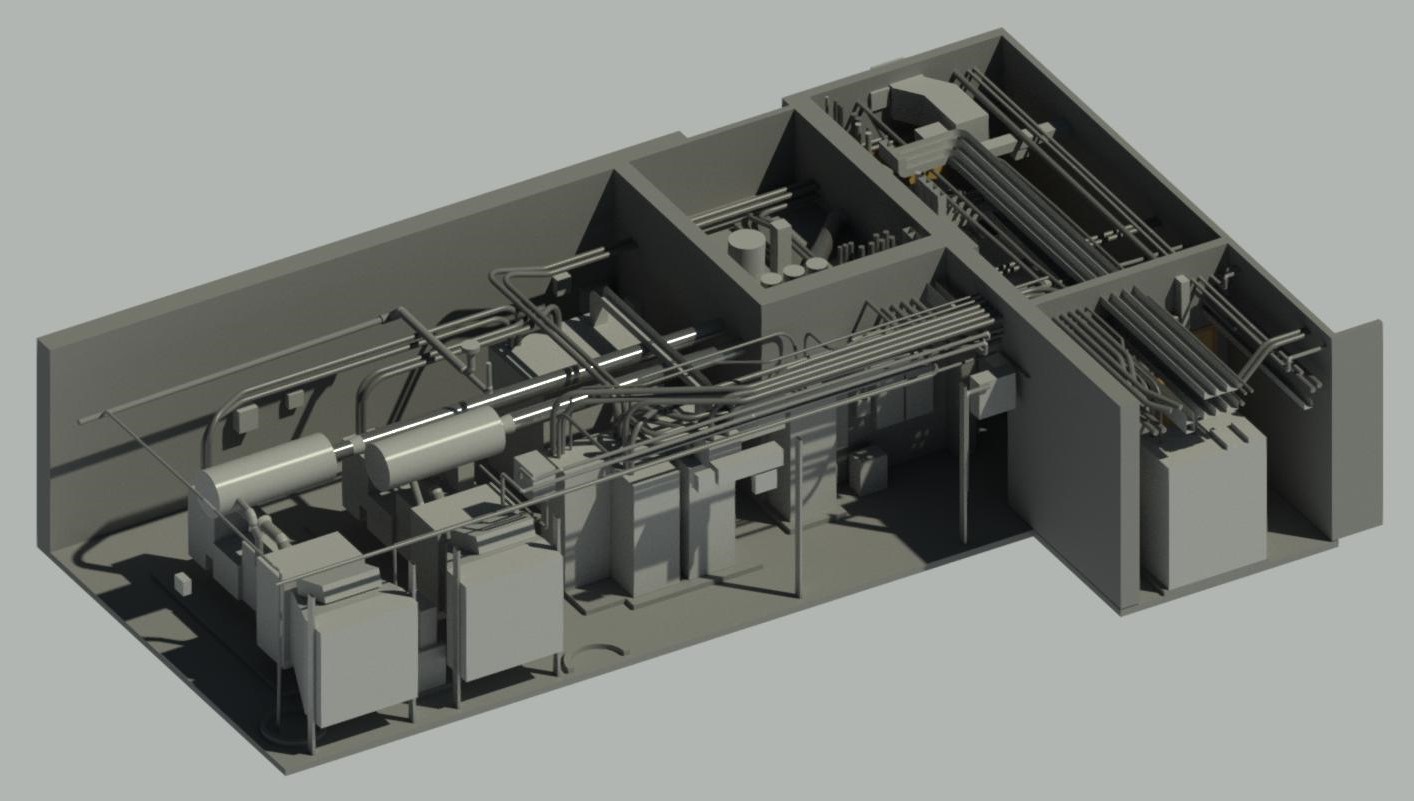

A time-sensitive LiDAR / Laser Scan and Revit model enabled electrical contractor to methodically coordinate the replacement of hospital back-up generators.

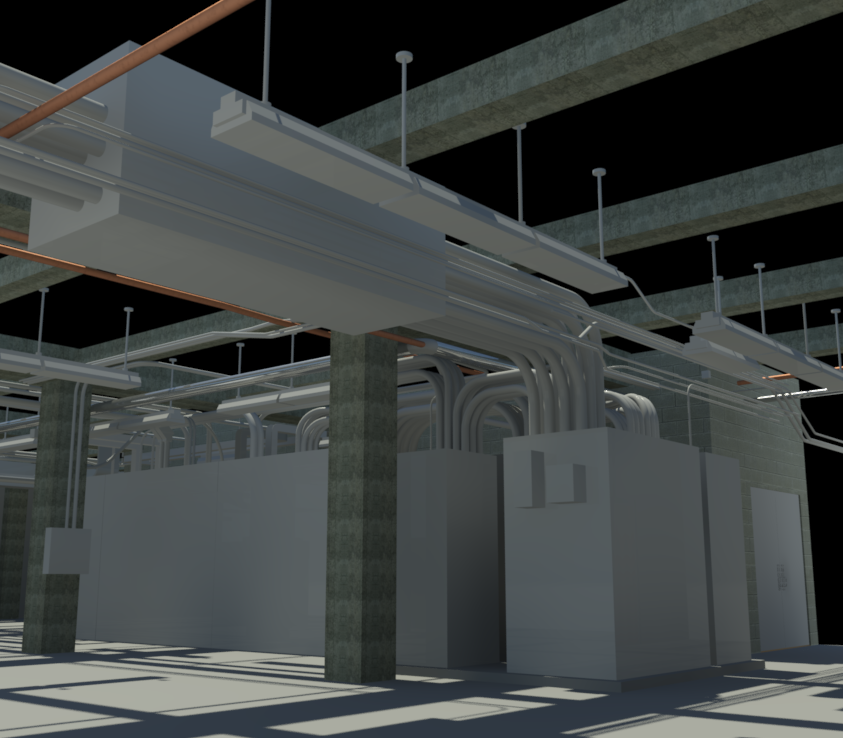

View ProjectNorth Kansas City Hospital

Preparing for a potential power outage is critical for all hospitals and health care facilities. When the regular electrical grid fails, hospitals rely on emergency generators to provide critical power for patient care systems. Eventually, these back-up generators need to be updated or replaced. Given that power outages can happen suddenly and without warning, the replacement process must be carefully planned to avoid putting the hospital at risk of a catastrophic power failure.

Rogue Visual Design’s rapid LiDAR scanning and CAD modeling process is significantly more efficient, more accurate, and less expensive than traditional documentation methods for capturing as-built layouts. Our work at North Kansas City Hospital demonstrates how our LiDAR scanning process expedites the documentation and design process for electrical contractors working on time-sensitive projects.

In 2021, an electrical engineering and construction company hired Rogue Visual Design to scan four rooms that housed the hospital's three emergency generators, electrical panels, and equipment. These generators ensured an uninterrupted source of power at North Kansas City’s Main Hospital which included their operating and emergency rooms. Once the final registration of the scans was complete, our proficient BIM team aligned the scans to existing Revit Models supplied and created from .pdf drawings by our client. Walls were adjusted to reflect the true as-built conditions. Additional components such as switchgear, conduit, cable tray, and generators documented in the scans were added to create the most complete and accurate picture of the generator equipment and rooms. This highly accurate scan-based replica model was then delivered to our client.

With the updated models provided by Rogue Visual Design, the electrical contractor had all the information needed to develop the effective design and procedures to complete the new generator improvements. At Rogue Visual Design, we are proud our work saves our clients time and money. It also allows them to complete complex designs and installations for critical projects such as this. Our clients were able to complete this project on a very tight schedule with no downtime for the power generating equipment.

In 2021, an electrical engineering and construction company hired Rogue Visual Design to scan four rooms that housed the hospital's three emergency generators, electrical panels, and equipment. These generators ensured an uninterrupted source of power at North Kansas City’s Main Hospital which included their operating and emergency rooms. Once the final registration of the scans was complete, our proficient BIM team aligned the scans to existing Revit Models supplied and created from .pdf drawings by our client. Walls were adjusted to reflect the true as-built conditions. Additional components such as switchgear, conduit, cable tray, and generators documented in the scans were added to create the most complete and accurate picture of the generator equipment and rooms. This highly accurate scan-based replica model was then delivered to our client.

With the updated models provided by Rogue Visual Design, the electrical contractor had all the information needed to develop the effective design and procedures to complete the new generator improvements. At Rogue Visual Design, we are proud our work saves our clients time and money. It also allows them to complete complex designs and installations for critical projects such as this. Our clients were able to complete this project on a very tight schedule with no downtime for the power generating equipment.

Old Whittier School

A vacant elementary school building with no electrical power nor floor plans needing Revit models for efficient renovation.

View ProjectOld Whittier School

The Old Whittier School in Kansas City, Kansas is an 86,000 square foot brick schoolhouse built in 1920. The school remained in operation until 1991 when it was replaced by the new Whittier School building constructed across the street. After sitting vacant for several decades and surviving fires, vandalism, and neglect; a developer purchased the property to renovate into an apartment complex. However, due to the age and history of the property, no existing architectural documentation for the building existed.

The architect tasked with designing the renovation reached out to Rogue Visual Design to document the interior of the building. As is often the case with vacant buildings, it lacked electrical power and indoor lighting. Our experienced LiDAR team navigated the basement and other dark areas by flashlight and was able to complete the scans of the three-story, multi-room structure in less than one day. The lack of illumination had no effect on our LiDAR equipment. The scan data was so detailed that it not only documented the building features, it also captured debris and the impacts of fire and neglect.

With the scans collected and registered, our BIM team quickly developed and delivered the Revit model to the architect. Our 3D CAD model provided both the architect and the developer with the most up to date, as-built conditions of the building. With this model, the architect had all the critical information needed to layout the new apartments.

At Rogue Visual Design, we are proud of the exquisite detail and unmatched accuracy delivered by our 3D Laser Scanners and professional team. Lacking electrical power and indoor lighting is just another “day at the office”. Our great depth of experience from documenting millions of square feet gives us the confidence that we can scan and deliver high quality models for all types of projects, regardless of the site conditions. Rogue Visual Design brings experience, efficiency, and reliability to every task. We look forward to bringing this same approach to your next project.

The architect tasked with designing the renovation reached out to Rogue Visual Design to document the interior of the building. As is often the case with vacant buildings, it lacked electrical power and indoor lighting. Our experienced LiDAR team navigated the basement and other dark areas by flashlight and was able to complete the scans of the three-story, multi-room structure in less than one day. The lack of illumination had no effect on our LiDAR equipment. The scan data was so detailed that it not only documented the building features, it also captured debris and the impacts of fire and neglect.

With the scans collected and registered, our BIM team quickly developed and delivered the Revit model to the architect. Our 3D CAD model provided both the architect and the developer with the most up to date, as-built conditions of the building. With this model, the architect had all the critical information needed to layout the new apartments.

At Rogue Visual Design, we are proud of the exquisite detail and unmatched accuracy delivered by our 3D Laser Scanners and professional team. Lacking electrical power and indoor lighting is just another “day at the office”. Our great depth of experience from documenting millions of square feet gives us the confidence that we can scan and deliver high quality models for all types of projects, regardless of the site conditions. Rogue Visual Design brings experience, efficiency, and reliability to every task. We look forward to bringing this same approach to your next project.

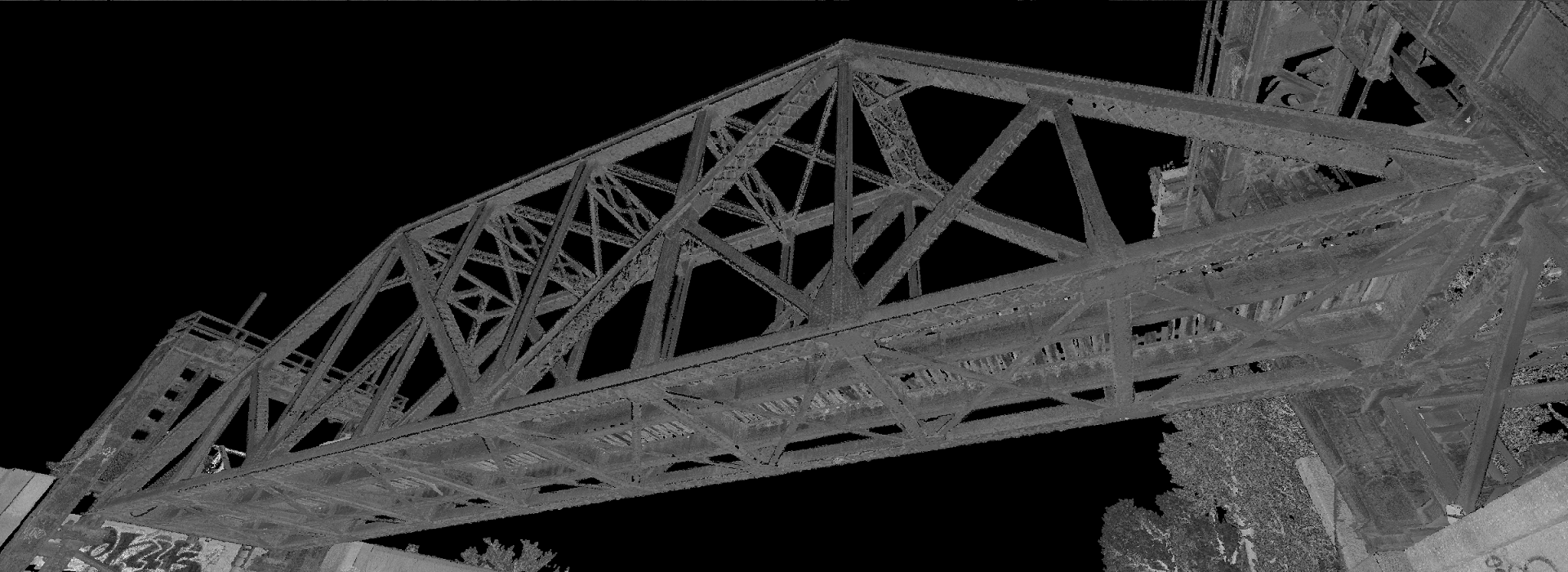

Smoky Hill Drainage

Using LiDAR scanning and photogrammetry to document several crucial, yet inaccessible, railroad components and factors in a seasonally flooding area.

View ProjectSmoky Hill Drainage

LiDAR is now regularly used to create the most detailed topographic maps of the earth’s surface. While airborne LiDAR and photogrammetry are preferred for some projects, stationary terrestrial LiDAR scanners are also able to create these maps and are the ideal scanning technology to use when highly accurate topographic or contour maps are needed.

Our recent work for the Kansas Department of Transportation (KDOT) illustrates our ability to provide extremely detailed LiDAR scans for civil engineering projects. In 2021, a surveying company working on a bridge replacement project contacted our Rogue Visual Design team to provide them with comprehensive scans for a proposed project. The project area was on Highway 40 in western Kansas. It included a railroad and rail bridge over the same tributary just upstream of the highway bridge being replaced. Both bridges carried traffic over a dry tributary of the Smoky Hill River that sometimes flooded during seasonal rains. The engineering team needed to understand how the traffic ways interacted with the local drainage system to appropriately design the new bridge. Most importantly, KDOT needed very accurate measurements of the railroad’s rail profile 1,000 feet in either direction of the two parallel bridges. This required precision is only possible with 3D laser scans.

Our recent work for the Kansas Department of Transportation (KDOT) illustrates our ability to provide extremely detailed LiDAR scans for civil engineering projects. In 2021, a surveying company working on a bridge replacement project contacted our Rogue Visual Design team to provide them with comprehensive scans for a proposed project. The project area was on Highway 40 in western Kansas. It included a railroad and rail bridge over the same tributary just upstream of the highway bridge being replaced. Both bridges carried traffic over a dry tributary of the Smoky Hill River that sometimes flooded during seasonal rains. The engineering team needed to understand how the traffic ways interacted with the local drainage system to appropriately design the new bridge. Most importantly, KDOT needed very accurate measurements of the railroad’s rail profile 1,000 feet in either direction of the two parallel bridges. This required precision is only possible with 3D laser scans.

Civil or topographic scanning can be challenging with a railway involved. Rogue Visual Design’s team was not permitted onto the railroad property for safety reasons. We had to find a way to gather the information without crossing into the railroad right-of-way. In this case, the railroad owned fifty feet south of the rails and two hundred and fifty feet north of the rails. Without breaching property lines, the scanning crew still had to capture the exact profile of the rails in the 3D laser scans.

With this challenge in mind, our experienced LiDAR crew made the trip out to the bridge location and completed the task in a single day. For this situation, the team utilized a telescoping tripod and, when possible, selected high elevation locations to scan over 2,000 feet of the railroad. The team then brought in our UAS drone to fill in any missing areas that were not visible in the LiDAR scans due to vegetation, berms, or the southern rail. As with all outdoor projects, the weather is a potential factor. Fortunately, our scanning crew and equipment were able to work through the several rain showers that day. Rogue Visual Design always comes through regardless of the conditions. We processed and hand-delivered the scans and drone data within five days of completing the on-site work.

Civil or topographic scanning can be challenging with a railway involved. Rogue Visual Design’s team was not permitted onto the railroad property for safety reasons. We had to find a way to gather the information without crossing into the railroad right-of-way. In this case, the railroad owned fifty feet south of the rails and two hundred and fifty feet north of the rails. Without breaching property lines, the scanning crew still had to capture the exact profile of the rails in the 3D laser scans.

With this challenge in mind, our experienced LiDAR crew made the trip out to the bridge location and completed the task in a single day. For this situation, the team utilized a telescoping tripod and, when possible, selected high elevation locations to scan over 2,000 feet of the railroad. The team then brought in our UAS drone to fill in any missing areas that were not visible in the LiDAR scans due to vegetation, berms, or the southern rail. As with all outdoor projects, the weather is a potential factor. Fortunately, our scanning crew and equipment were able to work through the several rain showers that day. Rogue Visual Design always comes through regardless of the conditions. We processed and hand-delivered the scans and drone data within five days of completing the on-site work.

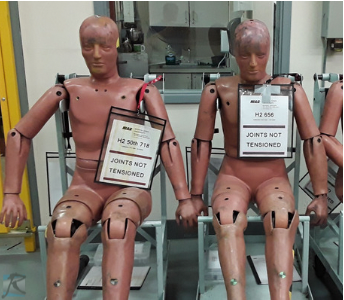

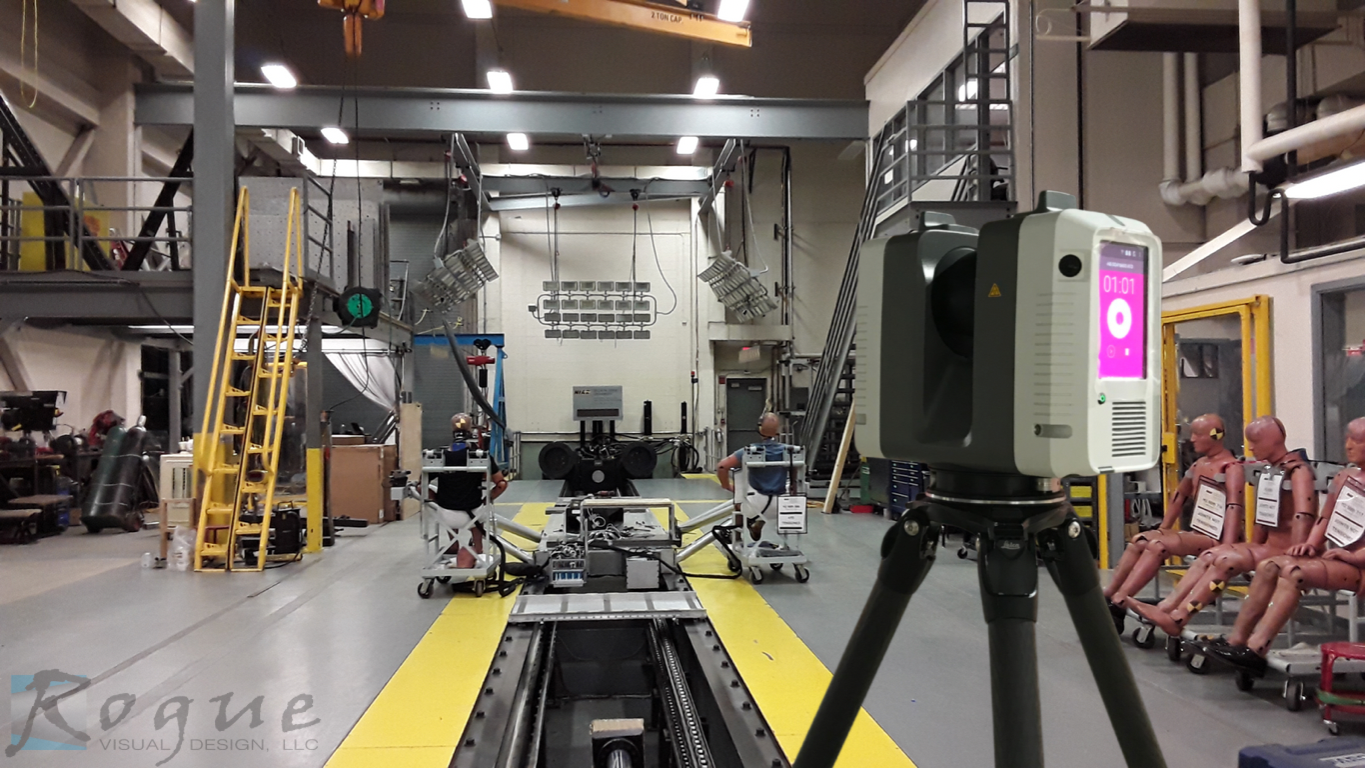

NIAR Crash Dynamics Lab

A client with in-house LiDAR capabilities requesting assistance with LiDAR / Laser Scanning and converting point clouds to Revit models.

View ProjectNIAR Crash Dynamics Lab

Rogue Visual Design was contacted by a construction company, working with the National Institute for Aviation Research (NIAR). They needed a scan of NIAR’s crash dynamics lab located on the Wichita State University (WSU) campus in Wichita, KS (The Air Capital of the World). NIAR performs research, testing, certification, and aviation and manufacturing technology training. Their experience with a wide range of projects gives them a unique viewpoint, and their capabilities, technology, and knowledge set them apart from any other test facility.

Our client has in-house scanning capabilities, but it was determined that hiring Rogue Visual Design to scan the project was more cost-effective than bringing in their crew from out of state. They had unpleasant experiences in the past with other LiDAR service providers. This left them understandably hesitant to outsource this critical component of the project.

Although Scan-to-BIM conversion was not part of Rogue's scope, our team felt that some areas would be difficult for someone unfamiliar with the site or the conversion process. We spent a little time setting up the Revit file and modeling a few crucial locations to ensure our client could complete their modeling within the limited time available. We shared best practices and tips on converting point clouds to Revit models. Rogue Visual Design is dedicated to our client’s success. Once again, the Rogue team's experience and technology came through. Our client was extremely satisfied with the point cloud and our team going above and beyond to assure their success.

Remember Rogue Visual Design for your next remodel. Our team dedicated to your success.

https://www.wichita.edu/research/NIAR/

https://www.wichita.edu/research/NIAR/Laboratories/crash.php

Our client has in-house scanning capabilities, but it was determined that hiring Rogue Visual Design to scan the project was more cost-effective than bringing in their crew from out of state. They had unpleasant experiences in the past with other LiDAR service providers. This left them understandably hesitant to outsource this critical component of the project.

Although Scan-to-BIM conversion was not part of Rogue's scope, our team felt that some areas would be difficult for someone unfamiliar with the site or the conversion process. We spent a little time setting up the Revit file and modeling a few crucial locations to ensure our client could complete their modeling within the limited time available. We shared best practices and tips on converting point clouds to Revit models. Rogue Visual Design is dedicated to our client’s success. Once again, the Rogue team's experience and technology came through. Our client was extremely satisfied with the point cloud and our team going above and beyond to assure their success.

Remember Rogue Visual Design for your next remodel. Our team dedicated to your success.

https://www.wichita.edu/research/NIAR/

https://www.wichita.edu/research/NIAR/Laboratories/crash.php

Mosaic Life Care

A time-sensitive remodel of Mosaic Life Care northeast wing, scanned amidst active demolition.

View ProjectMosaic Life Care

A structural engineering firm contacted Rogue Visual Design to scan at Mosaic Life Care in St. Joseph, Missouri. The hospital was remodeling the northeast wing of the third floor and they needed an accurate laser scan of the space to develop plans which reflected the existing site conditions. The structural design team had a Revit model; however, it was based on outdated drawings; Rogue to the rescue!

Mosaic Life Care is a nonprofit, community-based integrated health system. It serves the residents of northwest Missouri, northeast Kansas, southeast Nebraska, and southwest Iowa. It is the region's most extensive health system serving a population of approximately 270,000 and the region's largest employer of more than 4,000 people. Mosaic Life Care has a goal to commit ten percent of revenue to community benefit. They currently contribute more than $33 million in charity care each year.

In January 2021, the University of Missouri-Kansas City (UMKC) School of Medicine announced an expansion program. UKMC, together with Mosaic Life Care at St. Joseph, will use this program to help address the state's rural physician shortage. Health Resources and Services Administration (HRSA) gave UMKC a $7 million grant to start the new program. HRSA, the primary federal agency for improving access to healthcare services for uninsured, isolated, or medically vulnerable, will pay out the grant over four years.

To support an extremely tight design and construction schedule, Rogue dispatched a LiDAR crew to scan while site demolition was still in progress. As a result, the engineering team was able to start developing their model several weeks earlier. Rogue Visual Design returned to the hospital once interior demolition was complete to rescan the third floor. In less than 6 hours of total scan time, our LiDAR team captured over 21,000 square feet of a very active construction site - twice!

With the additional use of surveying targets, the Rogue team ensured the alignment of both sets of scans to each other and the existing Revit model. Rogue Visual Design provided the client with precise measurements of building elements such as pipes, windows, walls, steel, structural deviations, and more. Rogue completed the project during the Covid-19 pandemic when limited visits were permitted. Our process and technology reduce the time on-site required to gather the information, and fewer people are needed to complete the task. Rogue's small crew is the ideal team for the job. Let Rogue Visual Design's wealth of experience, cutting-edge technology, and adaptable problem-solving skills assist you in taking your project to the next level!

To support an extremely tight design and construction schedule, Rogue dispatched a LiDAR crew to scan while site demolition was still in progress. As a result, the engineering team was able to start developing their model several weeks earlier. Rogue Visual Design returned to the hospital once interior demolition was complete to rescan the third floor. In less than 6 hours of total scan time, our LiDAR team captured over 21,000 square feet of a very active construction site - twice!

With the additional use of surveying targets, the Rogue team ensured the alignment of both sets of scans to each other and the existing Revit model. Rogue Visual Design provided the client with precise measurements of building elements such as pipes, windows, walls, steel, structural deviations, and more. Rogue completed the project during the Covid-19 pandemic when limited visits were permitted. Our process and technology reduce the time on-site required to gather the information, and fewer people are needed to complete the task. Rogue's small crew is the ideal team for the job. Let Rogue Visual Design's wealth of experience, cutting-edge technology, and adaptable problem-solving skills assist you in taking your project to the next level!

Coronado Heights Park

A historical landmark, digitally archived for preservation purposes.

View ProjectCoronado Heights Park

There is a rather out-of-place hill northwest of Lindsborg, Kansas. The approximately 300-foot-tall mound is now known as "Coronado Heights Park" is owned and maintained by the Smoky Valley Historical Association. In the 1930s, the Works Progress Administration (WPA) built a picnic area and castle-like building on the top of the hill out of Dakota limestone. The view from this castle on the hill is spectacular, like something more at home in the Scottish Highlands than a rural area in Central Kansas. The Rogue Visual Design team had the opportunity to begin scanning the site as a training exercise, one that would showcase how the scans could be used for historical preservation purposes. Coronado Heights received its name from a local legend that claims Spanish Conquistador Francisco Vázquez de Coronado y Luján gave up his infamous search for the "seven cities of gold" and returned to Mexico on or near this site. Coronado allegedly visited central Kansas in 1541 on an expedition for the Native American city of Quivira, where trees hung with golden bells and even simple pots and pans were crafted from beaten gold. After hearing the "firsthand account" of a Franciscan priest in 1539, who claimed to have seen one of the cities, Coronado searched for the treasure.

Historical sites such as this deserve to be preserved physically through maintenance and renovation and digitally through the LiDAR/laser scanning process. With a digital copy of the structure and the surrounding area provided by Rogue Visual Design LLC, public works officials have what they need to essentially re-create the site and possess a permanent digital record of the structure that could outlast the actual buildings themselves.

For more information about Coronado Heights and a visitor's guide, visit https://www.visitlindsborg.com/coronado-heights

Coronado Heights received its name from a local legend that claims Spanish Conquistador Francisco Vázquez de Coronado y Luján gave up his infamous search for the "seven cities of gold" and returned to Mexico on or near this site. Coronado allegedly visited central Kansas in 1541 on an expedition for the Native American city of Quivira, where trees hung with golden bells and even simple pots and pans were crafted from beaten gold. After hearing the "firsthand account" of a Franciscan priest in 1539, who claimed to have seen one of the cities, Coronado searched for the treasure.

Historical sites such as this deserve to be preserved physically through maintenance and renovation and digitally through the LiDAR/laser scanning process. With a digital copy of the structure and the surrounding area provided by Rogue Visual Design LLC, public works officials have what they need to essentially re-create the site and possess a permanent digital record of the structure that could outlast the actual buildings themselves.

For more information about Coronado Heights and a visitor's guide, visit https://www.visitlindsborg.com/coronado-heights

Electrical Equipment Update

LiDAR / Laser Scan and Revit model for efficient design, fabricate, and installation of electrical equipment and conduits.

View ProjectElectrical Equipment Update

A new client contacted Rogue Visual Design needing help documenting an electrical room in Springfield, Missouri. They were tasked with removing and replacing the old switchgear. To minimize surprises during installation, the electrical contractor required a detailed Revit model to complete the switch and route conduit. In slightly over two hours, our LiDAR team scanned and photographed the electrical/battery room.

The client had previously attempted to use LiDAR; however, the point clouds files they received were incomplete, too massive, or otherwise unusable. Unlike previous scanning attempts, Rogue provided them with a complete and usable point cloud as well as an accurate Revit model.

Rogue specializes in 3D laser scanning and Scan-to-BIM. Unlike other companies, Rogue’s sole focus is reality capture and CAD modeling. In addition to the most precise Revit models possible, our experienced personnel have the proper tools to provide valuable and useable documentation. This client has returned to Rogue Visual Design for further laser scanning needs since this project. Allow Rogue to do it correctly the first time!

The client had previously attempted to use LiDAR; however, the point clouds files they received were incomplete, too massive, or otherwise unusable. Unlike previous scanning attempts, Rogue provided them with a complete and usable point cloud as well as an accurate Revit model.

Rogue specializes in 3D laser scanning and Scan-to-BIM. Unlike other companies, Rogue’s sole focus is reality capture and CAD modeling. In addition to the most precise Revit models possible, our experienced personnel have the proper tools to provide valuable and useable documentation. This client has returned to Rogue Visual Design for further laser scanning needs since this project. Allow Rogue to do it correctly the first time!

Atlas F Missile Silo

A decommissioned missile silo, digitally archived for remodeling and preservation purposes.

View ProjectAtlas F Missile Silo

The Rogue Visual Design team recently had the opportunity to visit a decommissioned Atlas F missile silo located in Wilson, Kansas. This former Atlas F missile silo (known as Site 8 - Wilson, Kansas) was part of the 550th Strategic Missile Squadron out of Schilling AFB and was among the last Atlas ICBM bases to be built. Site 8 was only in use 4 years (1961-1965) before it was deemed obsolete and decommissioned. The Atlas F silo complex consisted of the main missile silo and an underground tunnel connecting to the Launch Control Center (LCC). The LCC and silo were only accessible through an entryway located above-ground. The facility was equipped with an emergency escape hatch that could be accessed from within the LCC. There was additional support equipment and personnel areas above ground which were contained in two Quonset huts of about 4,000 square feet each. Atlas F silos were built on approximately 20 acres of land, 5 of the acres being contained inside a 7-foot chain link fence. The 3D LiDAR scans provided by Rogue Visual Design will assist the silo’s owner in the restoration and remodeling of what was once home to a Cold War era weapon of mass destruction. The owner’s end goal is to turn the silo into a conceptual representation of a Mars or Moon base. A place where people can come to learn about cutting-edge, self-sufficient technologies as well as have camps, and a space for special events. Rogue Visual Design's 3D laser scans will aid in the planning and restoration of this historical site.

The 3D LiDAR scans provided by Rogue Visual Design will assist the silo’s owner in the restoration and remodeling of what was once home to a Cold War era weapon of mass destruction. The owner’s end goal is to turn the silo into a conceptual representation of a Mars or Moon base. A place where people can come to learn about cutting-edge, self-sufficient technologies as well as have camps, and a space for special events. Rogue Visual Design's 3D laser scans will aid in the planning and restoration of this historical site.

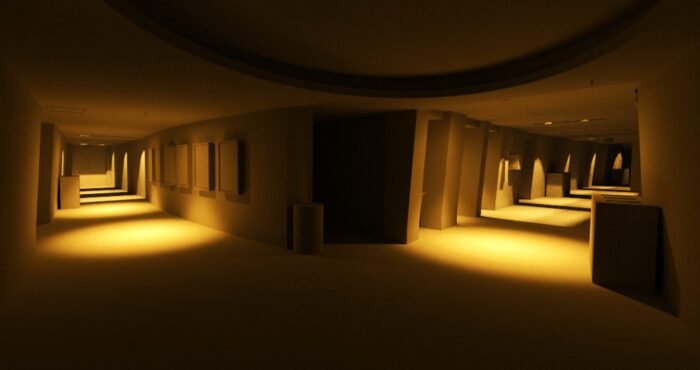

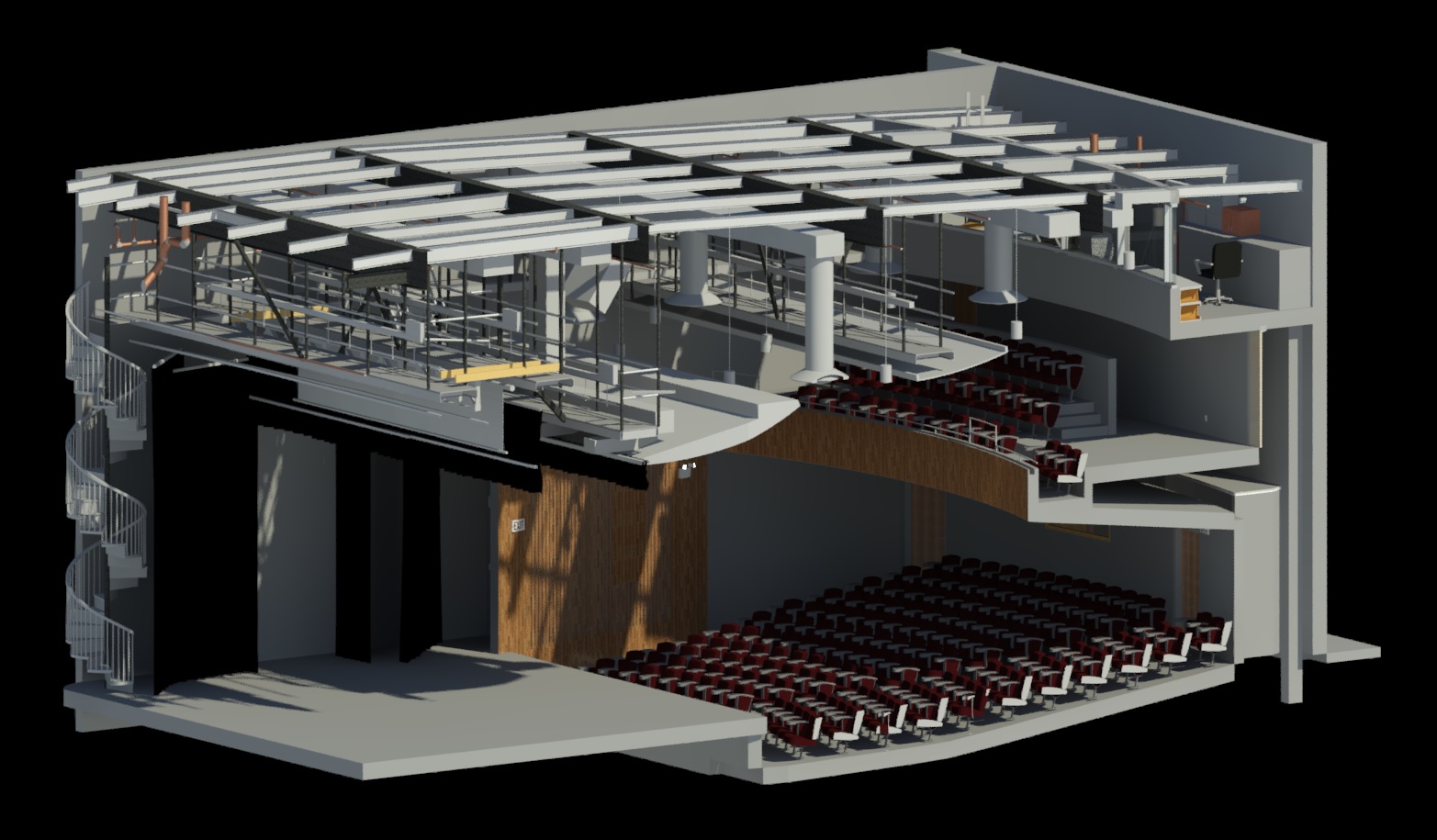

The City Theatre of Independence

LiDAR / Laser Scan a stage, lighting, catwalks, and curtains within short window of opportunity to develop a 3D SketchUp model.

View ProjectThe City Theatre of Independence

Rogue Visual Design was approached by a director representing “The City Theatre of Independence” (CTI) to laser scan and model their theatre and stage. He wanted a model that would allow him and other directors to efficiently design stage sets, lighting, and aid in curtain placement. With an accurate 3D SketchUp model, he would know the sightline from every seat, the limits of curtain tracks, and the space available on the stage for sets and backdrops.

The Rogue Team experienced a typical set of challenges that confront them on many projects - historic architecture combined with “newer” construction. The theatre space had some additional challenges in that there were extra props and set building pieces scattered about from past productions. These were not intended to be part of the 3D model but had to be scanned as there was no practical or efficient way to remove them all. With this site being a theatre, catwalks and curtains (including their track systems) presented a particularly unique challenge. As the sets from previous shows were disassembled, CTI would immediately start building the next set and begin on-stage rehearsals - meaning an extremely limited window between productions for scanning.

The LiDAR scans taken by the Rogue LiDAR team digitally captured the stage, house, seats/seating, balcony, lighting booth, and the overhead catwalks. The CAD model that was produced exposed even the tiniest details: every light mount, outlet, and curtain down to the complex system of tracks that suspend them was visible in the CAD model we produced. Documenting the 164-seat Powerhouse Theatre for The City Theatre of Independence was an opportunity for Rogue Visual Design to help preserve the arts and culture of Independence. Thanks to the accuracy of the laser scans, the model CTI received will assure any future changes to the space can be made using the most up-to-date information with laser-accurate measurements.

CTI has a rich history of community involvement, including a recent fundraiser for cancer research. They are also involved in several theatre events corresponding with various Holidays and local festivals/celebrations. Their first production was in 1980, and since that time they have performed hundreds of plays. CTI performs their plays at the “Powerhouse Theatre” in the Roger T. Sherman Center located at 201 N Dodgion St. in Independence, MO. For more information: https://citytheatreofindependence.org/

The Rogue Team experienced a typical set of challenges that confront them on many projects - historic architecture combined with “newer” construction. The theatre space had some additional challenges in that there were extra props and set building pieces scattered about from past productions. These were not intended to be part of the 3D model but had to be scanned as there was no practical or efficient way to remove them all. With this site being a theatre, catwalks and curtains (including their track systems) presented a particularly unique challenge. As the sets from previous shows were disassembled, CTI would immediately start building the next set and begin on-stage rehearsals - meaning an extremely limited window between productions for scanning.

The LiDAR scans taken by the Rogue LiDAR team digitally captured the stage, house, seats/seating, balcony, lighting booth, and the overhead catwalks. The CAD model that was produced exposed even the tiniest details: every light mount, outlet, and curtain down to the complex system of tracks that suspend them was visible in the CAD model we produced. Documenting the 164-seat Powerhouse Theatre for The City Theatre of Independence was an opportunity for Rogue Visual Design to help preserve the arts and culture of Independence. Thanks to the accuracy of the laser scans, the model CTI received will assure any future changes to the space can be made using the most up-to-date information with laser-accurate measurements.

CTI has a rich history of community involvement, including a recent fundraiser for cancer research. They are also involved in several theatre events corresponding with various Holidays and local festivals/celebrations. Their first production was in 1980, and since that time they have performed hundreds of plays. CTI performs their plays at the “Powerhouse Theatre” in the Roger T. Sherman Center located at 201 N Dodgion St. in Independence, MO. For more information: https://citytheatreofindependence.org/

Flint Hills Resources

LiDAR scanning an 11.5 acre asphalt cement plant to develop a 2D site plan and 3D Revit model.

View ProjectFlint Hills Resources

An asphalt cement plant in Dubuque, Iowa was replacing their MCC building. All new control cable would also be routed throughout the facility. The electrical engineering team needed accurate site information to route thousands of feet of new cable tray. Similarly, the structural team needed the information to locate and design cable tray supports.

One of our LiDAR specialist traveled to site. In 19 hours they documented the 11.5 acres facility with 421 individual laser scans. Back at the office the scans were processed, registered, and geolocated using survey control captured while scanning. Our modeling team converted the point cloud into a Revit model and developed a 2D site plan.

An asphalt cement plant in Dubuque, Iowa was replacing their MCC building. All new control cable would also be routed throughout the facility. The electrical engineering team needed accurate site information to route thousands of feet of new cable tray. Similarly, the structural team needed the information to locate and design cable tray supports.

One of our LiDAR specialist traveled to site. In 19 hours they documented the 11.5 acres facility with 421 individual laser scans. Back at the office the scans were processed, registered, and geolocated using survey control captured while scanning. Our modeling team converted the point cloud into a Revit model and developed a 2D site plan.

Naval Air Station Fallon

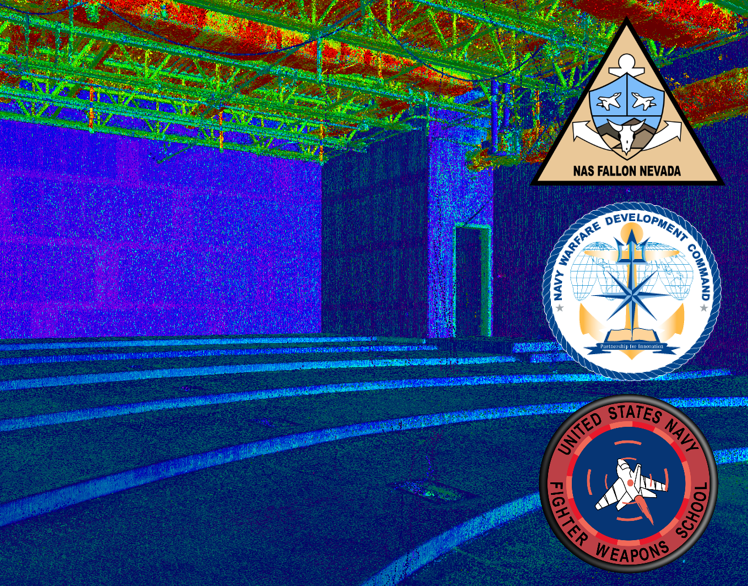

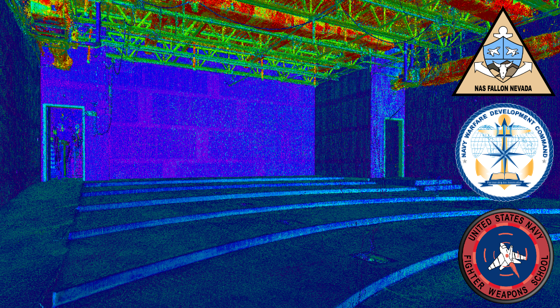

LiDAR /Laser Scan of four separate training/lecture rooms to provide a detailed 3D CAD model.

View ProjectNaval Air Station Fallon

The Naval Aviation Warfighting Development Center located at Naval Air Station Fallon, Nevada (Top Gun) built a state-of-the-art facility to maintain its mandate as the center of excellence for naval aviation training and tactics development. Custom tables would be manufactured and installed in several of the training/lecture rooms. Our client needed an accurate as-built 3D CAD model of four rooms. Not only did they need to know location and length of the walls, they needed the profile of each riser, the size and location of each electrical box embedded in the floor, and the size and location of each conduit penetrating the floor. To document these rooms with a steel/laser tape or total station would take an average of eight hours per room, two people, and provide only a few hundred data points. Rogue Visual Design sent one LiDAR specialist who scanned all four rooms, generating several hundred million data points, in less than eight hours. Our specialist processed the scan data that evening so it was ready for 3D CAD modeling the following day.

The Naval Aviation Warfighting Development Center located at Naval Air Station Fallon, Nevada (Top Gun) built a state-of-the-art facility to maintain its mandate as the center of excellence for naval aviation training and tactics development. Custom tables would be manufactured and installed in several of the training/lecture rooms. Our client needed an accurate as-built 3D CAD model of four rooms. Not only did they need to know location and length of the walls, they needed the profile of each riser, the size and location of each electrical box embedded in the floor, and the size and location of each conduit penetrating the floor. To document these rooms with a steel/laser tape or total station would take an average of eight hours per room, two people, and provide only a few hundred data points. Rogue Visual Design sent one LiDAR specialist who scanned all four rooms, generating several hundred million data points, in less than eight hours. Our specialist processed the scan data that evening so it was ready for 3D CAD modeling the following day.

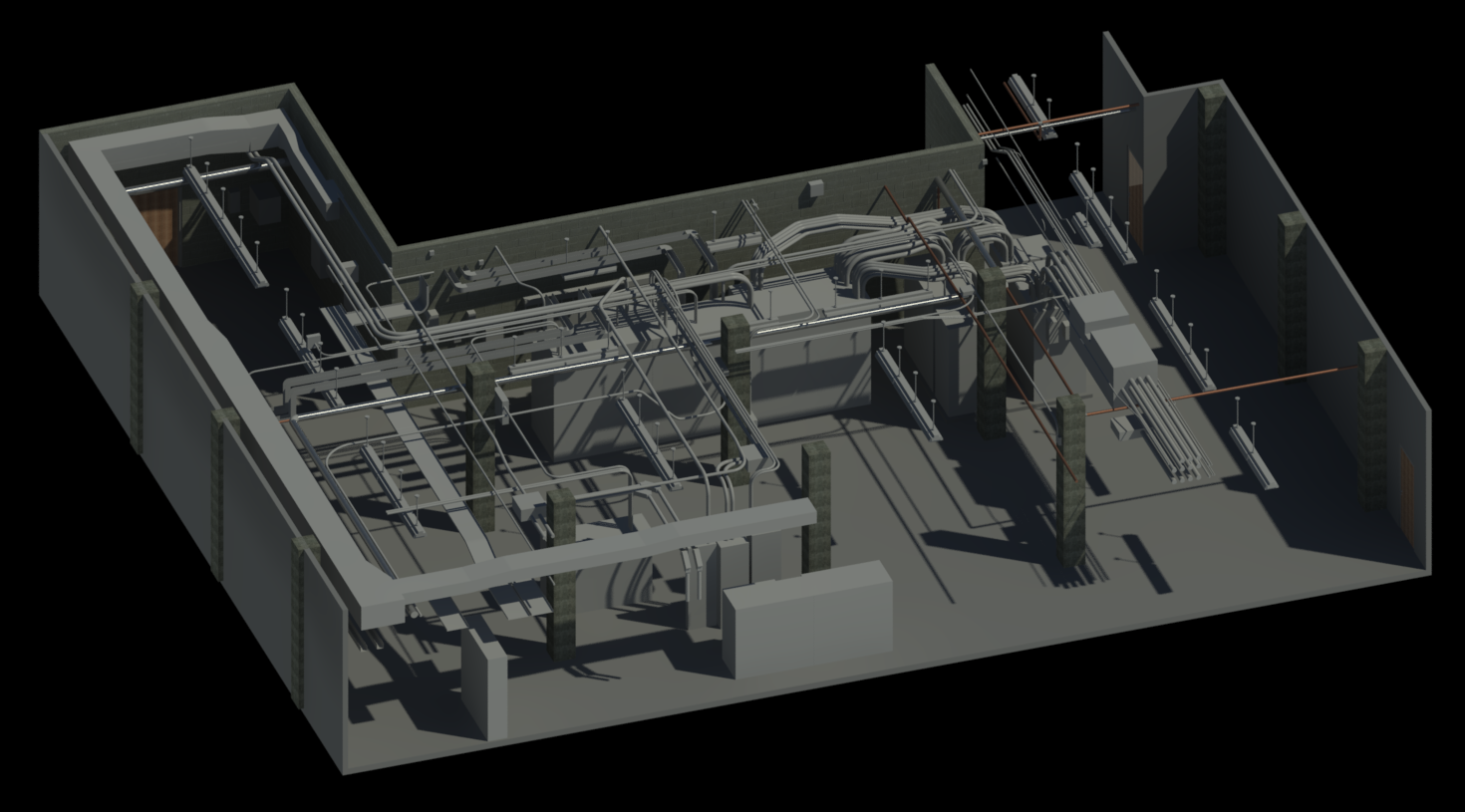

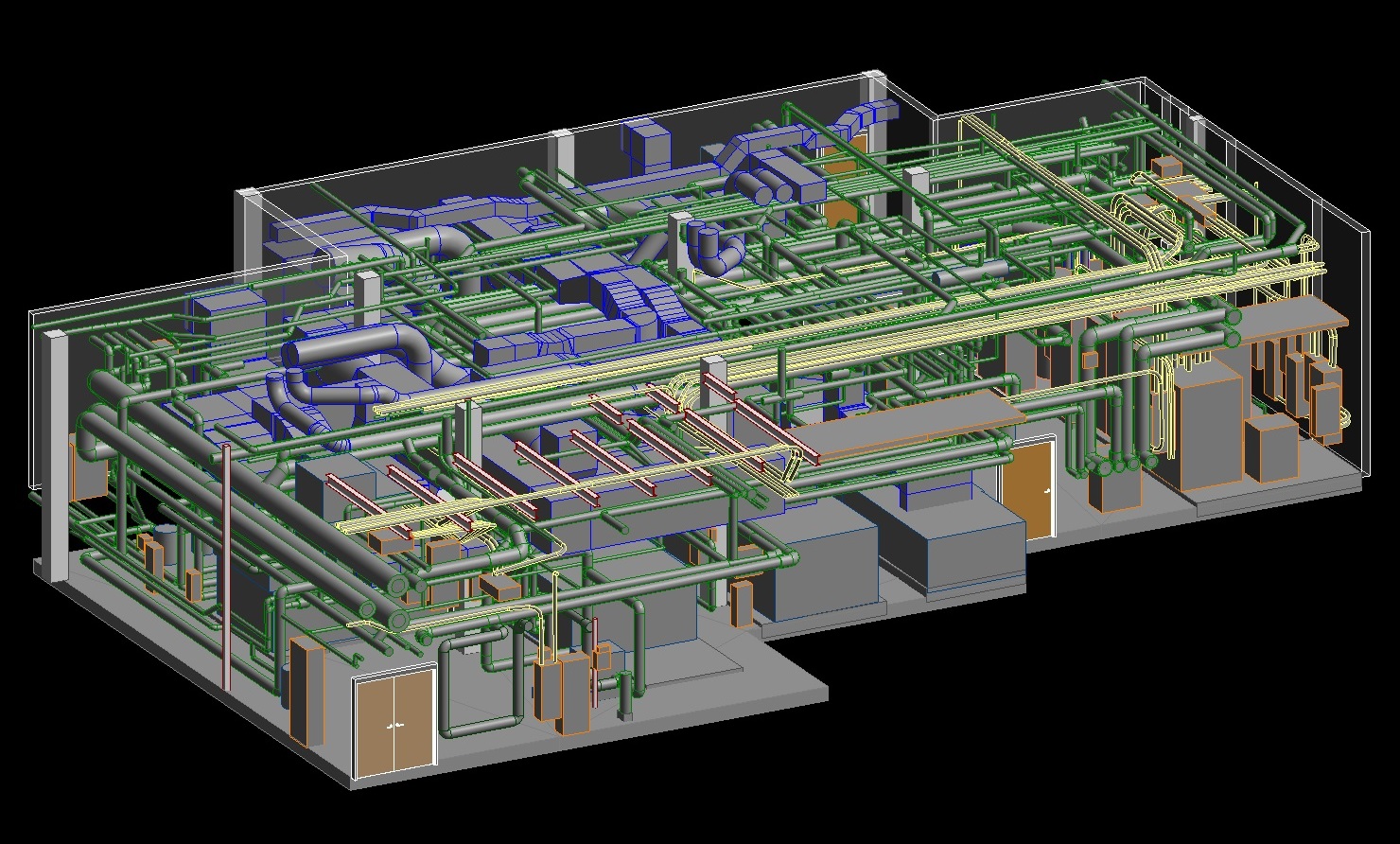

Bryan Medical Center East Campus

LiDAR scanning and Revit modeling to support the methodical coordination of a time-sensitive air handling system replacement.

View ProjectBryan Medical Center East Campus

Regular upgrades and improvements to the air handling systems in health care facilities are crucial to minimizing airborne infection risks and optimizing overall patient care. As such, a primary concern of all health care facilities is that any needed improvements should be completed as quickly and as efficiently as possible. However, the challenge faced by many health care facilities is that these needed upgrades are often complex and require very detailed documentation in order to design and plan the efficient installation of these critically important upgrades.

At Rogue Visual Design, our highly accurate scanning process has demonstrated the capability to more efficiently produce the intricately detailed models needed for the design and installation of complex air handling systems. Our work at Bryan Medical Center, an award-winning nonprofit hospital in Lincoln, Nebraska, provides an example of the swift and effective documentation we can provide for health care facilities in need of replacing or upgrading their air handling systems.

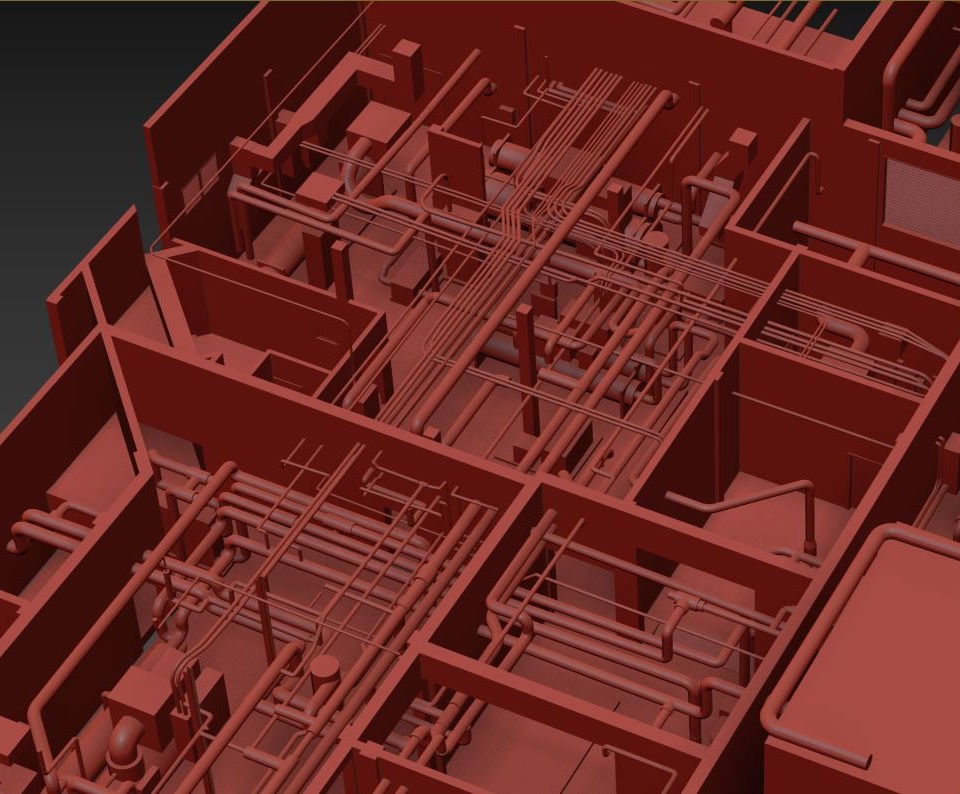

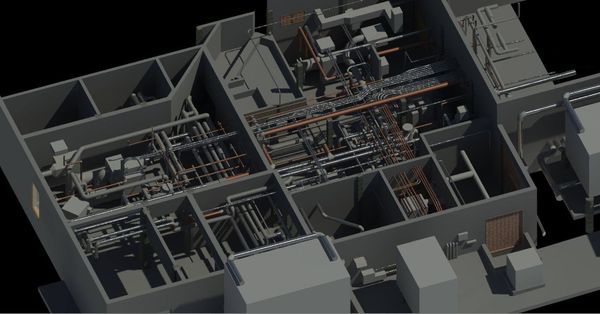

Bryan Medical Center, East Campus, is a large, nonprofit hospital complex with many rooms and buildings housing patients on a one quarter mile square campus. The air handling systems for one of the main buildings of this large facility are located in two rooms separated by 6 floors. The engineering and design team needed precise documentation of the air handling system, which included: pipe configuration, duct layout, equipment geometry/locations, electrical panels, conduits, cable trays, and the architectural and structural shell they occupy.

Rogue Visual Design’s experienced LiDAR crew scanned the site and handed the scan/point cloud data over to the modeling team who converted the data into two highly accurate Revit models. Most notably, Rogue’s skilled team took a minimum of 70% less time to scan and document the site compared to traditional survey methods. The completed BIM models were then used to design, plan, and install the new air handling systems. Our time-saving documentation method allowed for a less expensive renovation that was completed on a much shorter project schedule. As such, by employing Rogue Visual Design during the design phase, Bryan Medical Center was able to more efficiently upgrade their air handling systems.

Bryan Medical Center’s clinics can be found throughout Nebraska and there are also affiliated clinics in surrounding states. For more information about Bryan Medical Center, please visit: https://www.bryanhealth.com/.

At Rogue Visual Design, our highly accurate scanning process has demonstrated the capability to more efficiently produce the intricately detailed models needed for the design and installation of complex air handling systems. Our work at Bryan Medical Center, an award-winning nonprofit hospital in Lincoln, Nebraska, provides an example of the swift and effective documentation we can provide for health care facilities in need of replacing or upgrading their air handling systems.

Bryan Medical Center, East Campus, is a large, nonprofit hospital complex with many rooms and buildings housing patients on a one quarter mile square campus. The air handling systems for one of the main buildings of this large facility are located in two rooms separated by 6 floors. The engineering and design team needed precise documentation of the air handling system, which included: pipe configuration, duct layout, equipment geometry/locations, electrical panels, conduits, cable trays, and the architectural and structural shell they occupy.

Rogue Visual Design’s experienced LiDAR crew scanned the site and handed the scan/point cloud data over to the modeling team who converted the data into two highly accurate Revit models. Most notably, Rogue’s skilled team took a minimum of 70% less time to scan and document the site compared to traditional survey methods. The completed BIM models were then used to design, plan, and install the new air handling systems. Our time-saving documentation method allowed for a less expensive renovation that was completed on a much shorter project schedule. As such, by employing Rogue Visual Design during the design phase, Bryan Medical Center was able to more efficiently upgrade their air handling systems.

Bryan Medical Center’s clinics can be found throughout Nebraska and there are also affiliated clinics in surrounding states. For more information about Bryan Medical Center, please visit: https://www.bryanhealth.com/.

Charless Place

Rogue Visual Design aided in renovating Charless Place, St. Louis, using 3D scans to create a precise Revit model, preserving its historic charm.

View ProjectCharless Place